One of the in-efficiencies of Lead-Acid batteries is that a current run through the battery even when fully charged and the Volt never grow. This also accomplishes balancing cells or batteries in series over time. When it comes to Lithium chemistry is the efficiency very high and no current bleed through without the volt increase. Using individual Lithium cells for a battery requires a very precise solution to balance each cell, this can often be solved with devices intended for managing battery packs for remote-controlled airplanes. When looking at a series of whole modules or batteries is devices not that easy to come by and the amount of energy needed to consume can be much higher. This could be the case if using two Tesla Modules in series for a 48 Volt battery or building a 24 Volt battery from two Battleborn 12 Volt batteries in series. Even these modules are very similar can many charges and discharge cycles bring this out of balance so one part charges higher than the other.

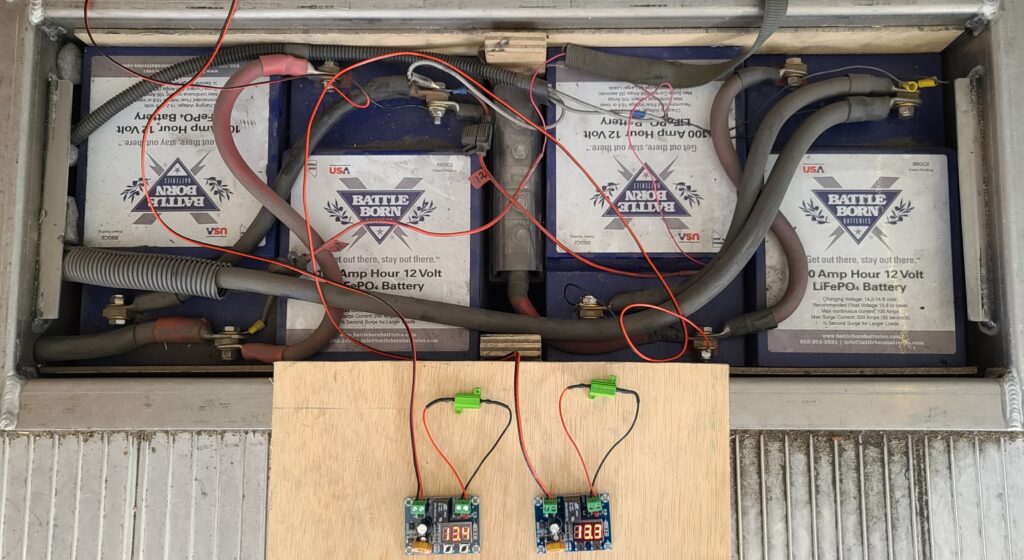

We have a 24 Volt Battery Bank in the trailer consisting of 2x2 12 Volt Battleborn batteries. A solution, of course, could be to get 24 Volt batteries to begin with but based on the wish to have batteries that could the "borrowed" to other in need of a 12 Volt battery and the fact the trailer is all aluminum and conductive we wanted to have a fuse in the middle of the battery box that could cut any shorting of a cable.

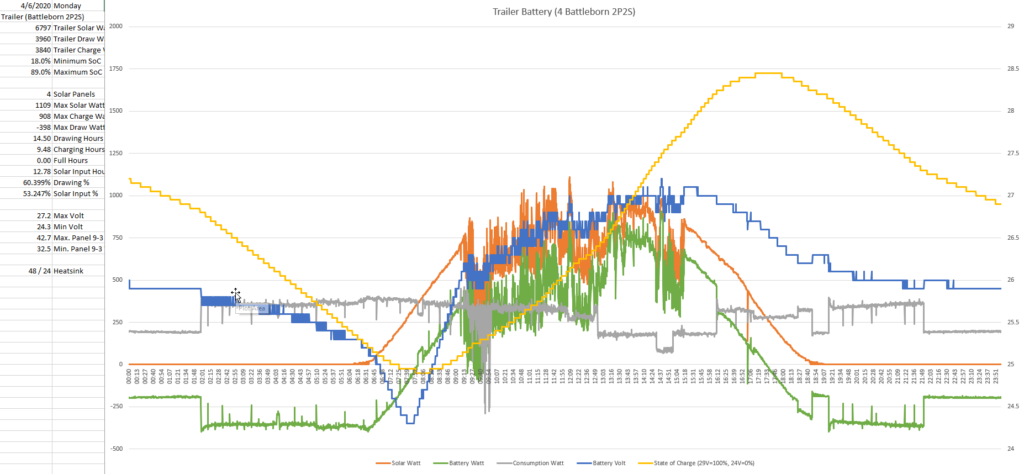

This setup now has the potential to get out of balance and over more than 2 years of hard use and abuse was that the case. One part of the battery never charged more than 80% State of Charge and when drained ran out of power when the other part still had 20% of the Energy left. The graph below is a day when the State of Charge went to 20% (Yellow) on the whole battery bank, the voltage (Blue) started dropping fast because of one side being almost drained. If this had continued much longer has the Battleborn battery on one side disconnected to protect the internal cells.

The Battleborn Battery Bank is charged to 28.8 Volt or 14.4 Volt for each half when balanced. If the Voltage on one side gets to be over ~15.2 Volt is the internal protection of the battery disconnecting, this happened all the time during the Absorption phase of our charging. The 15.2 Volt caused the other side to be 13.6 Volt and that is not enough to finish the full charge of a Battleborn battery so we ended up with only one had of the battery fully charged and this kept on being worse and worse for each day.

The Battleborn Battery Bank is charged to 28.8 Volt or 14.4 Volt for each half when balanced. If the Voltage on one side gets to be over ~15.2 Volt is the internal protection of the battery disconnecting, this happened all the time during the Absorption phase of our charging. The 15.2 Volt caused the other side to be 13.6 Volt and that is not enough to finish the full charge of a Battleborn battery so we ended up with only one had of the battery fully charged and this kept on being worse and worse for each day.

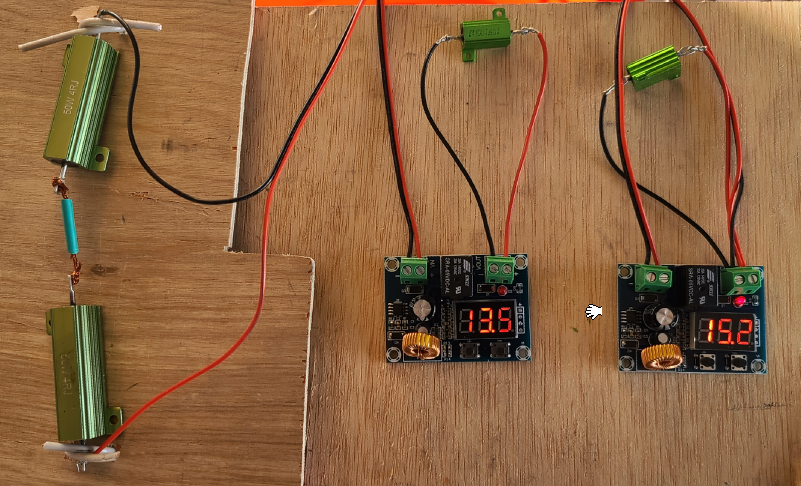

One of the biggest problems balancing the whole battery pack is the amount of energy needed to remove and the higher voltage. With simple voltage protectors and large wat resistors bought from Amazon was a simple system built able to handle several Ampere of balancing current. The devices are Voltage protector and cut the power on the output based on the Input Voltage. The protector has been programmed to connect the resistor if the Volt is over 14.7 Volt and disconnect when it is below 14.5 Volt. This ensures the balancing only happens on one part of the battery bank and always only during the absorption charge cycle. Because the system was so unbalanced, to begin with, was the standard 100 Ohm resistors for one side put in parallel with a 20 Ohm resistor to speed up the balancing. When the Battery Bank is now balanced can the 100 Ohm resistor easily keeps it balanced.

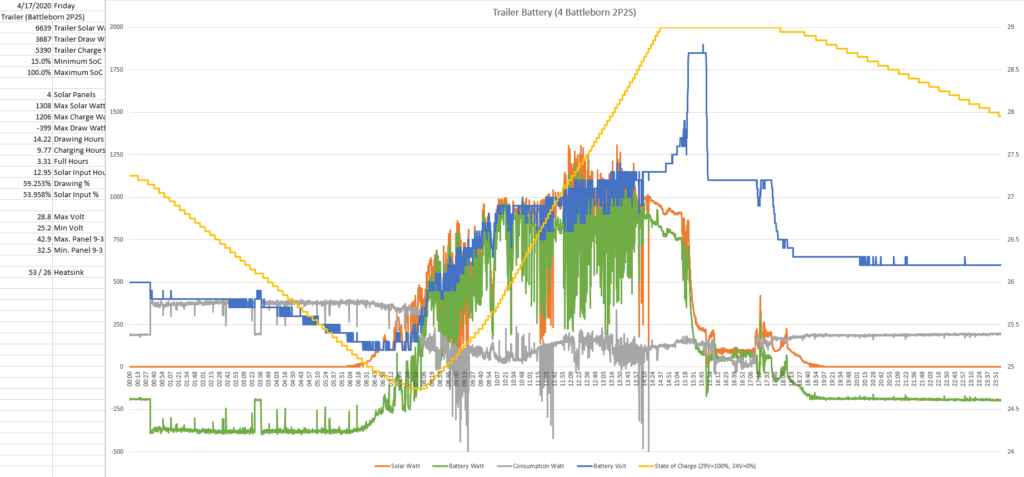

After the balancing was the battery bank again drawn down to 20% State of Charge (Yellow) an the Battery Volt (Blue) stay much more stable.

The balancing is going to be mounted permanently on the Battery Bank with some wires with small fuses connecting to the Terminals.

This approach can also be used when building a 48 Volt Battery Bank from Tesla Modules. Each 6S Tesla Module is balanced with simple balancers and each 24 Volt half balanced with a simple resistor setup. The precision for the cells needs to be 0.01 Volt or less, but the modules can be balanced with a 0.1 Volt precision that this simple system can accomplish.

Great idea! I have 24 BattleBorn Batteries that are having the same issue at my off grid Solar Cellular site. They are appx 1 year old or around 380 cycles. Usually down to around 50% each day. In the afternoon at full charge, one bank will go up to ~15.5 volts and Internal BMS will shut down. It’s really hard on the charge controllers and often the equipment at the site reboots when the inverter kicks off which is bad for business.

I am running 6 In parallel and then connected 4 in series for 48v. Would the small resistors be enough to bring them back into balance each day? I am trying to come up with a solution that is the same as yours but it will need to be larger due to the larger pack. I suspect I might have a few bad batteries but it’s too early to tell.

I had a similar issue, One 12 Volt bank was only at 60% SoC when the other was 100%. Battleborn recommends you once a year disconnect and charges each 12 Volt battery bank to 100% with a regular charger. Then reconnect it to a higher voltage bank.

I did not have a strong charger so I put a 12 Volt inverter as a load with a 250 Watt resistive heater on the high bank until I had consumed enough power for each 12 Volt part to have identical volt when not loaded. After the two banks got balanced has it not been a problem with the small resistors I have added to keep it in balance. Each day is only a small amount of energy needed to be adjusted.

The last time I was at the site I brought a 50 amp 12 volt charger with me and used it to charge up the lower voltage packs until they were all pretty close. A few weeks later it was drifting again. For now I have only been limiting charging to 55.4v as one of the strings hits around 14.3v at that voltage. Other strings only make it to around 13.4-13.5.

I installed a PacketFlux monitoring device so I could SNMP monitor the pack voltages remotely. I just ordered the same little boards that you used and also a few resistors. Hopefully it will get things back in order.

What are your thoughts on moving to Tesla modules in a remote unmanned site like this? Tesla lower voltages are not a problem for the equipment up there. We can use the BattleBorns at other grid connected sites as they make great standby UPS batteries. I have 5 Tesla Modules that I installed in my RV last summer (Your setup was my inspiration!). They have been working flawlessly. If I do this I would probably go with 10 or 12 modules. I have the EVTV BMS in my RV and would probably do something similar at the site. It would have a lot more capacity which would help with winter coming and use less propane from the Genset which we currently only fire up on cloudy days.

Where did you buy those resistors?

I’m trying to balance a string of 4 100aH 48V packs

I found the resistors on Amazon. the important part is to consider the Watt with the high voltage of the batteries. So you want to stay under the rated watt. Looking at a single battery is maximum volt 15 Volt. U = R * I and P = U * I. Eliminate the current (I) can tell what wattage we need for a resistor. P = U * U / R. So with a 15 Volt entered is P = 225 / R. Going with 100 Ohm resistor is the minimum power rating 2.25 Watt. I do not recommend using it to the maximum limit and would add a 5-10 time factor for heating. So a 100 Ohm 10 Watt resistor is what I would use. If you need lower Ohm resistors add multiple in parallel that does not add additional heating in each resistor. Also, ensure you do not place these resistors on the batteries directly. they are going to get hot.

Something like these looks good: https://www.amazon.com/LM-YN-Wirewound-Electronic-Industrial/dp/B071P23MPX