The story of our System

We started out with just a few solar panels to keep our 4 lead-acid house batteries charged in the hope we also could use the power generated. We mainly stayed in RV parks in the beginning and only used our batteries when traveling.

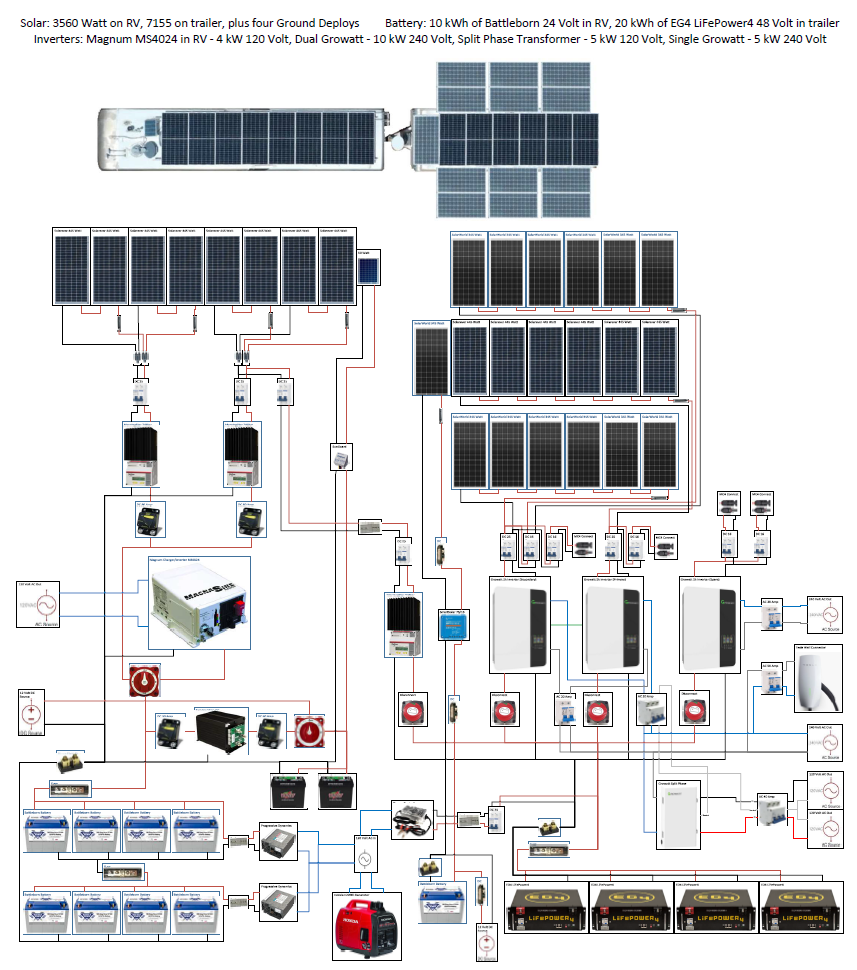

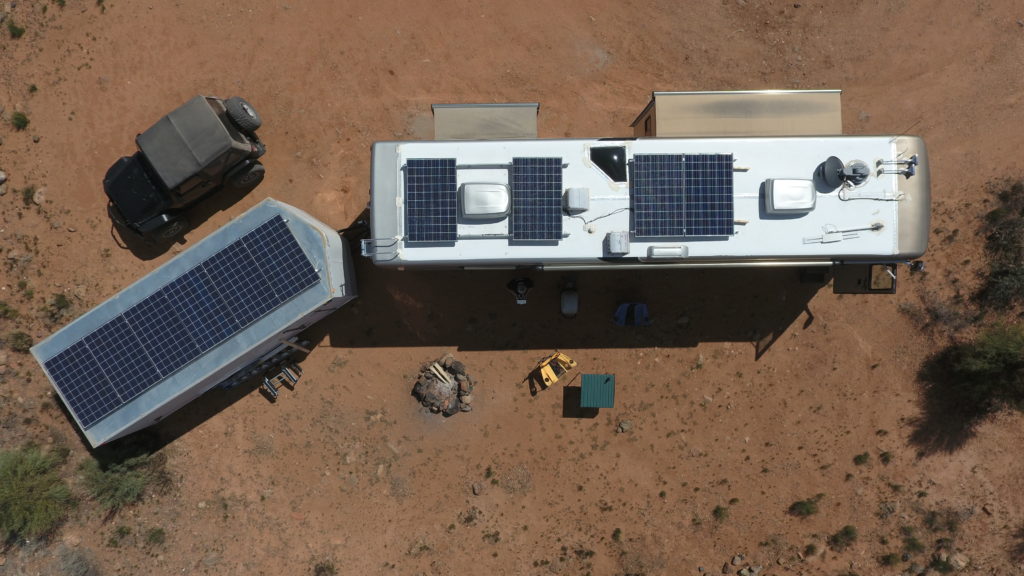

The current system has 10700 Watt of large residential solar panels mounted on the trailer (7150 Watt) and RV (3550 Watt). We have upgraded the battery system to use Battleborn heated Lithium Iron Phosphate batteries in a 24 Volt battery bank, 4000 Watt Inverter. We almost always boon-dock and even when staying in an RV park (dumping and washing cloth) are we not plugged in. We can run both Air Condition units with the setup in the trailer that we also use for charging the Tesla.

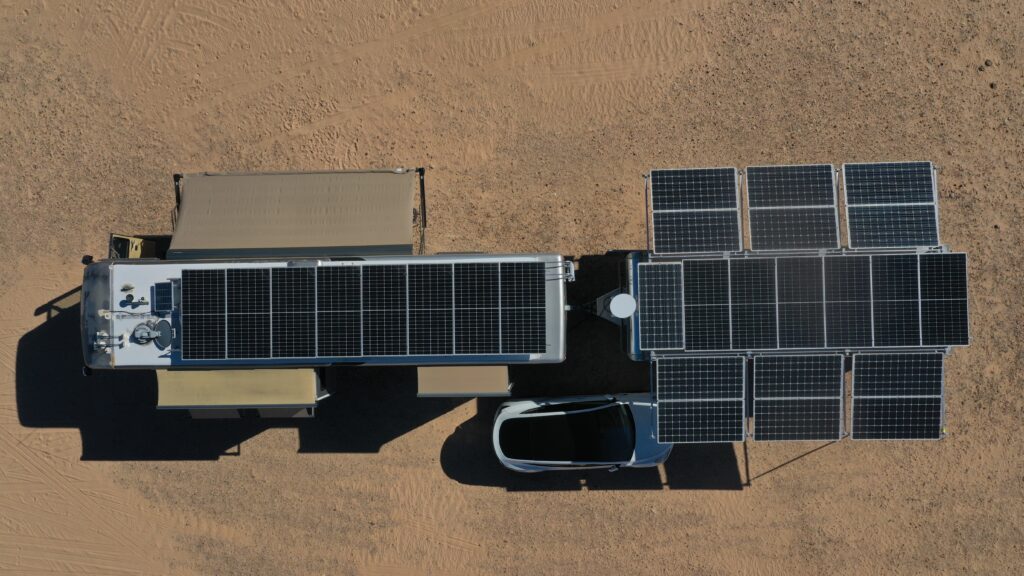

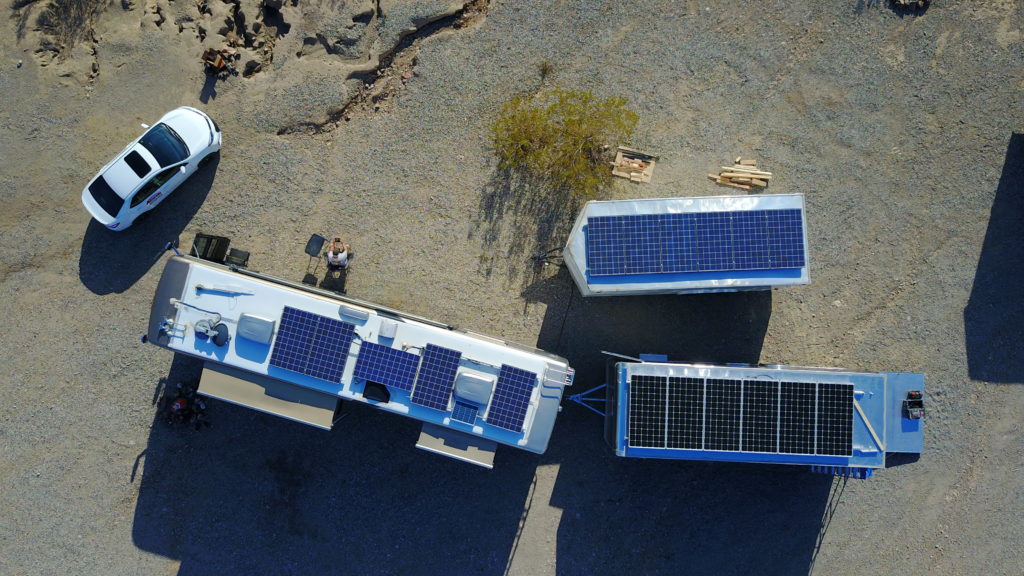

The complete mobile setup deployed.

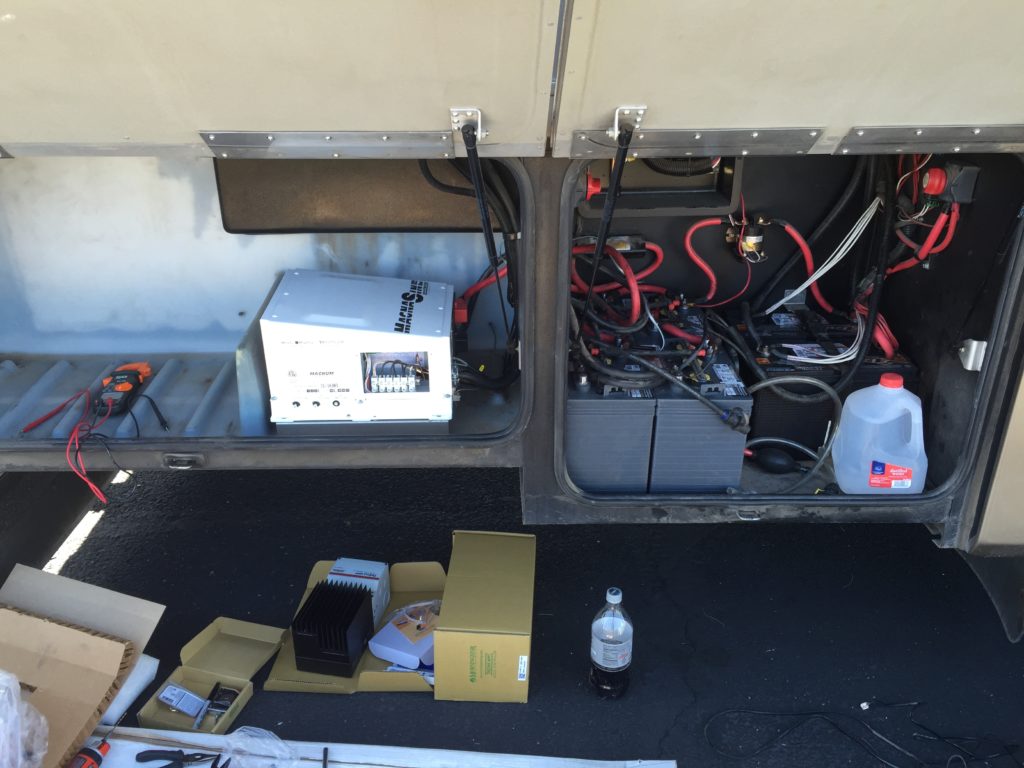

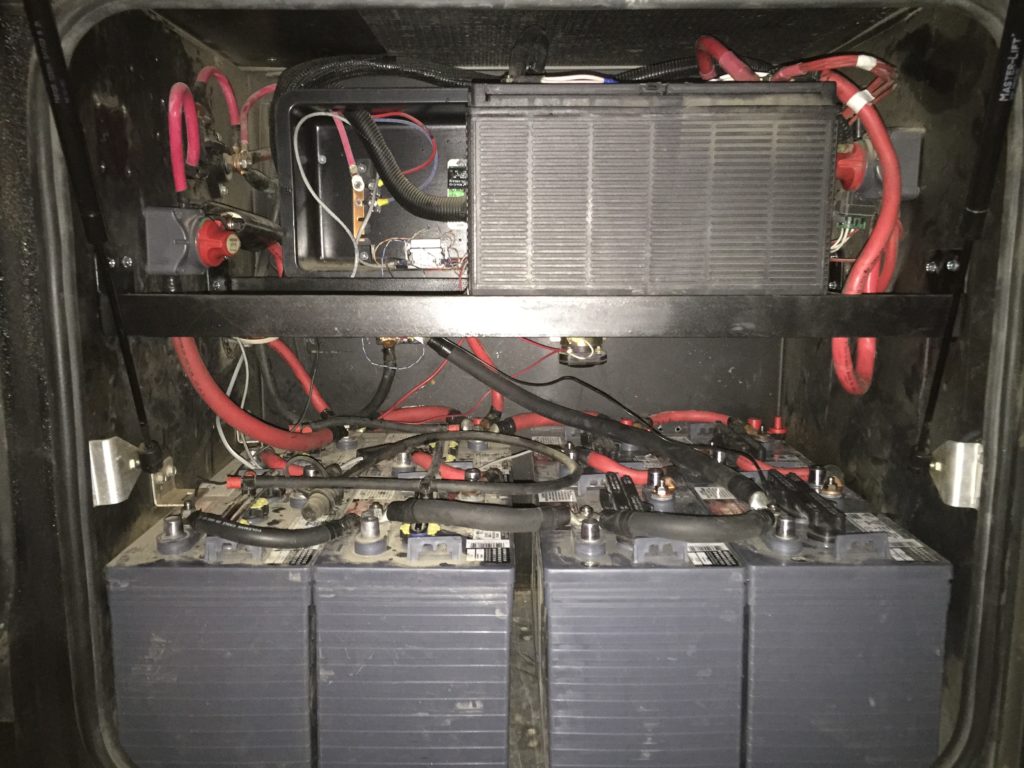

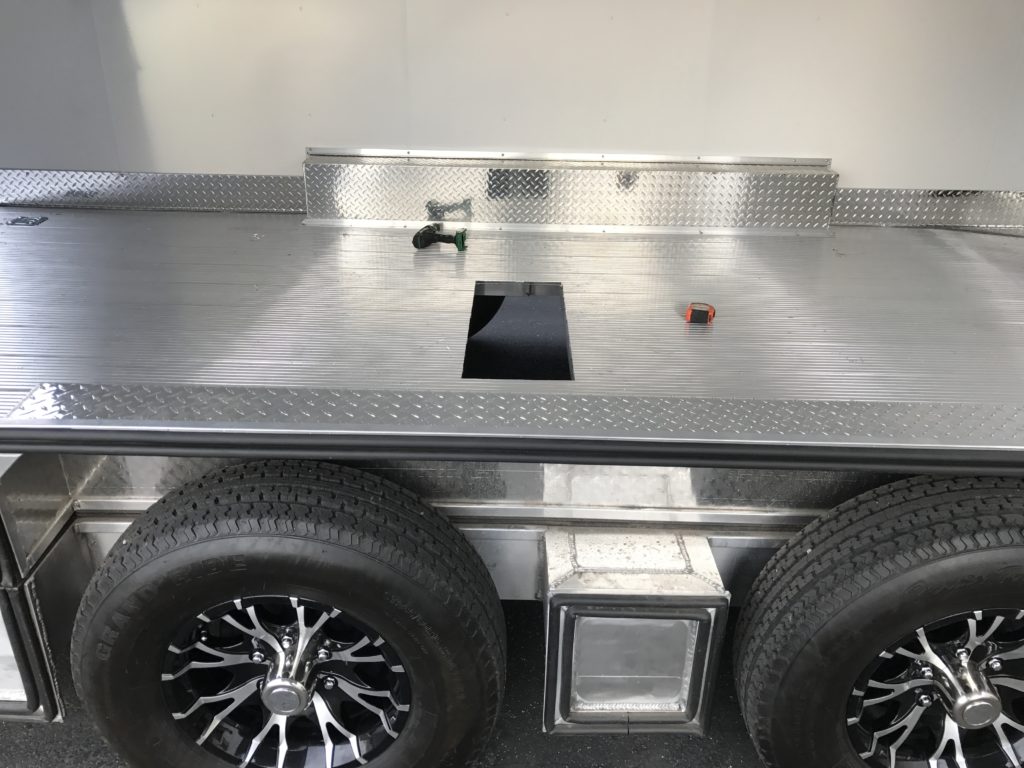

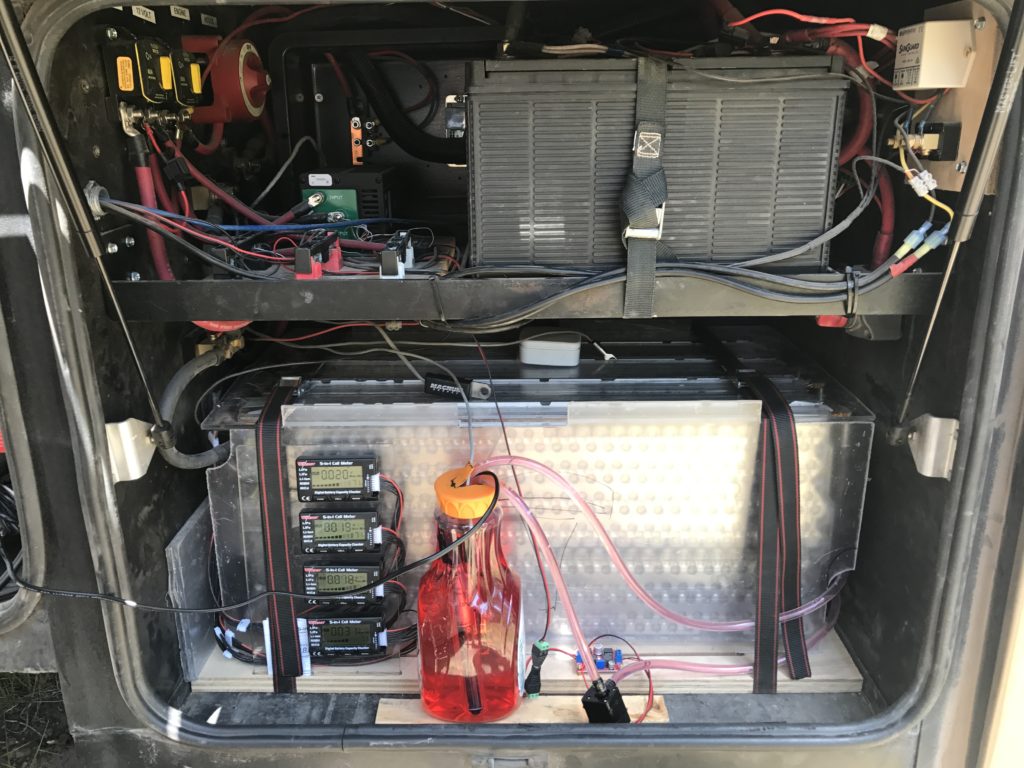

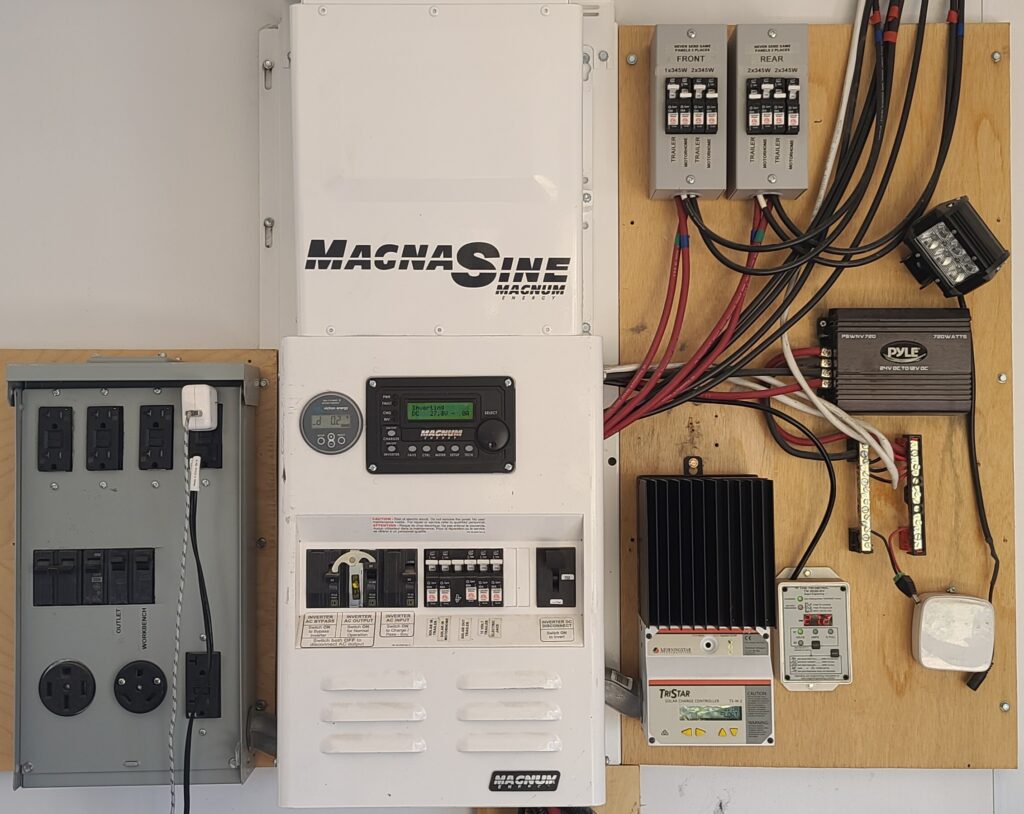

Everything is in 2 bays at the rear of the RV.

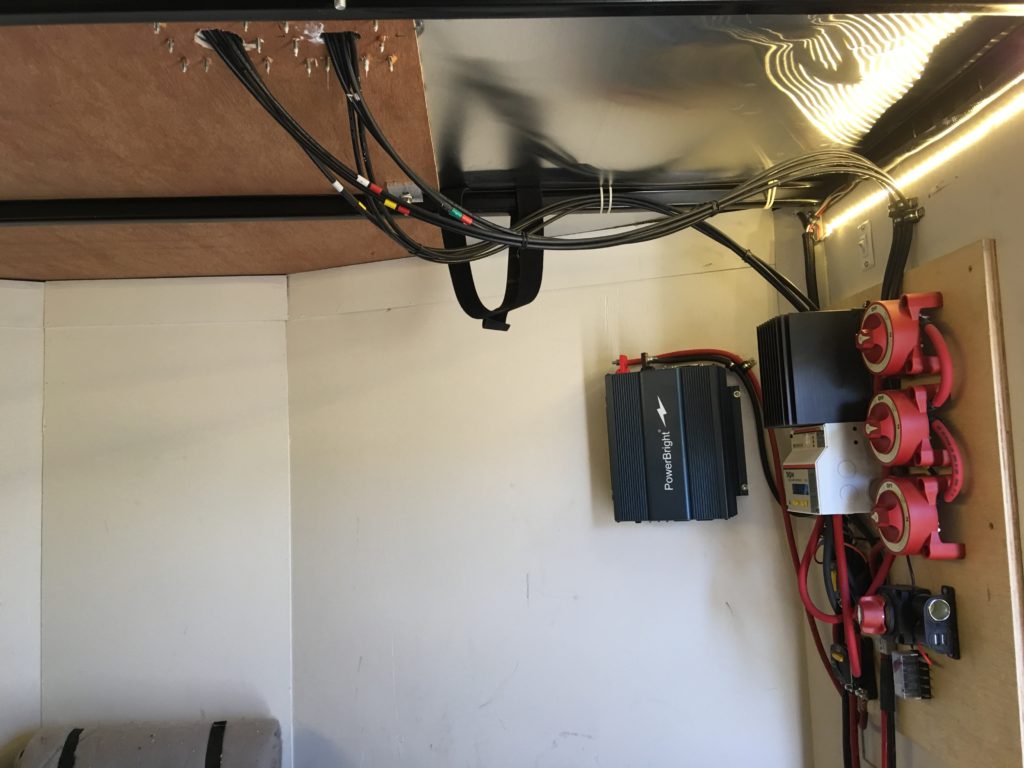

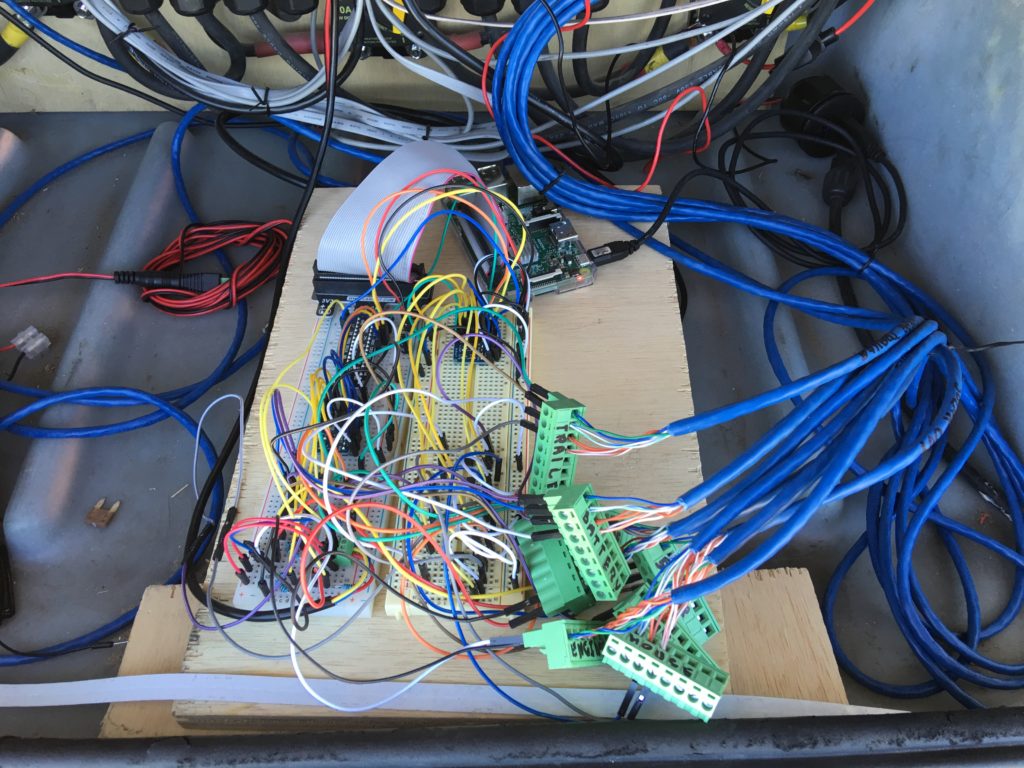

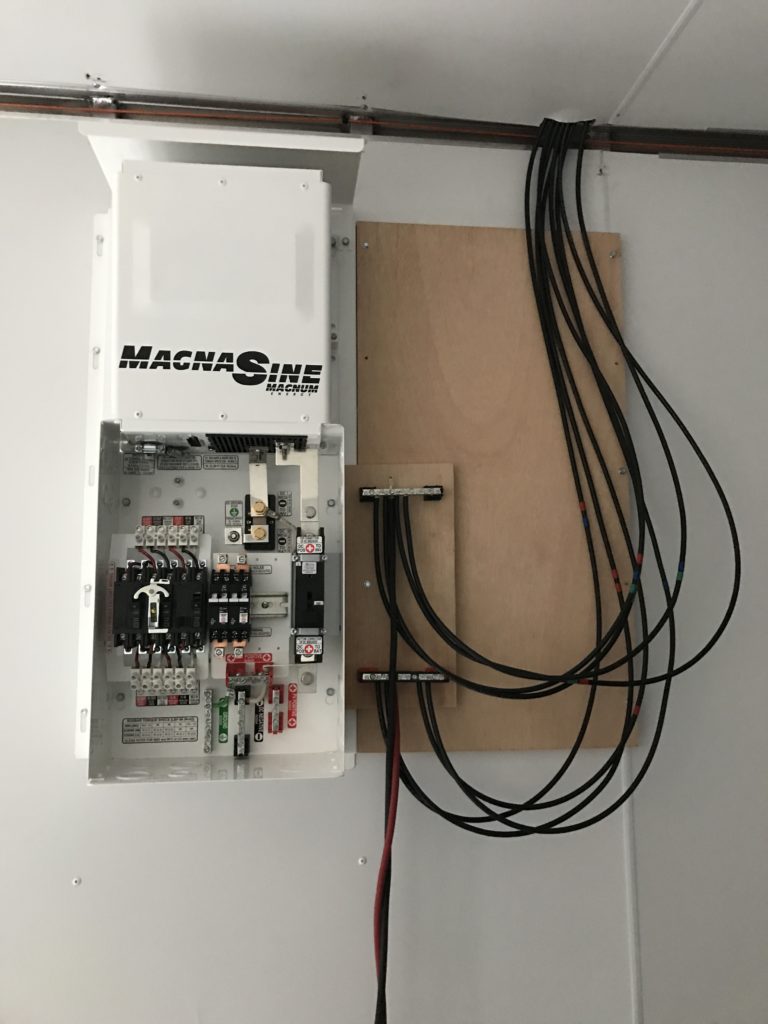

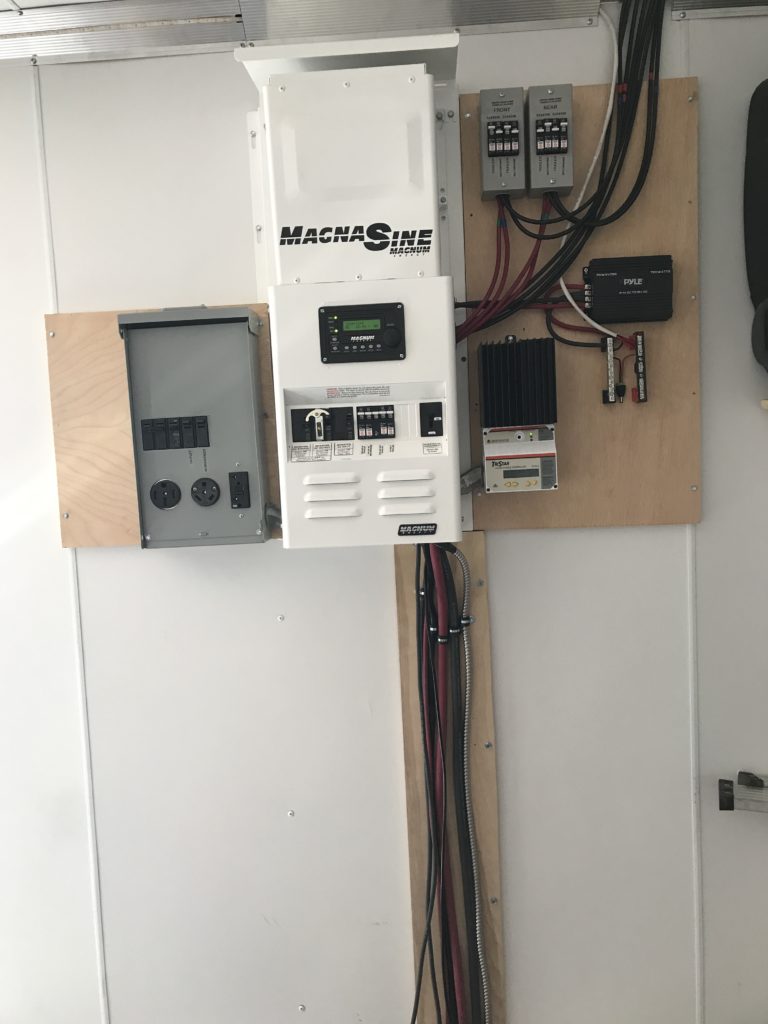

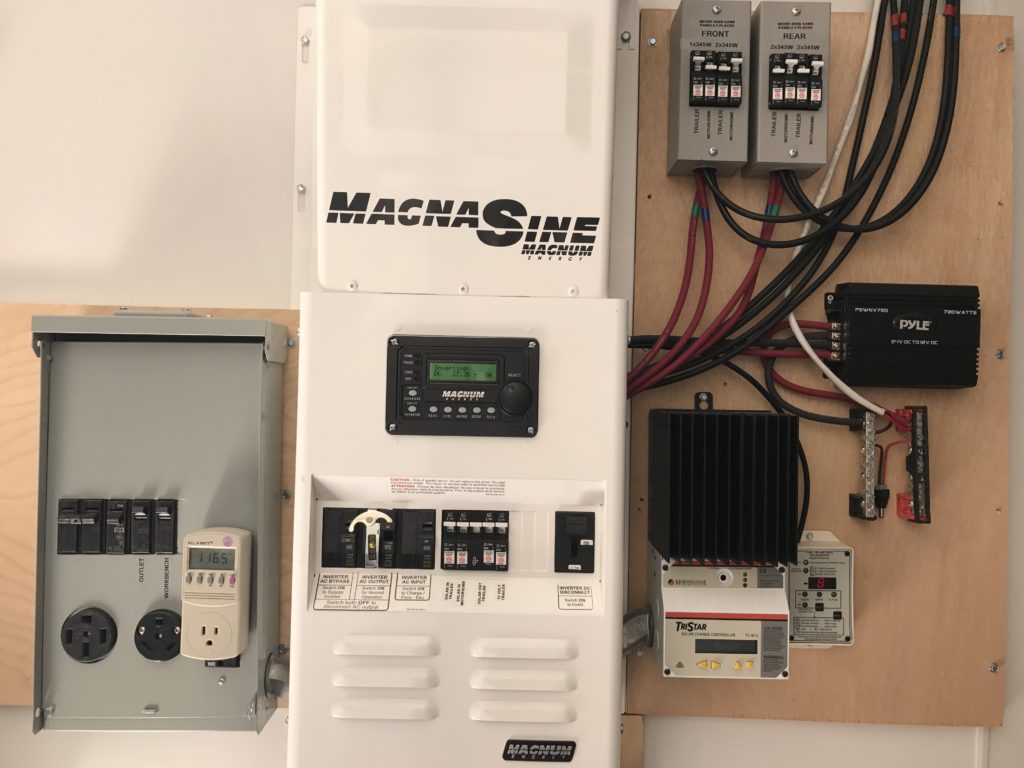

The electronics in the trailer.

The winter setup with 23 kW of solar panels.

The latest wiring diagram.

June 2014

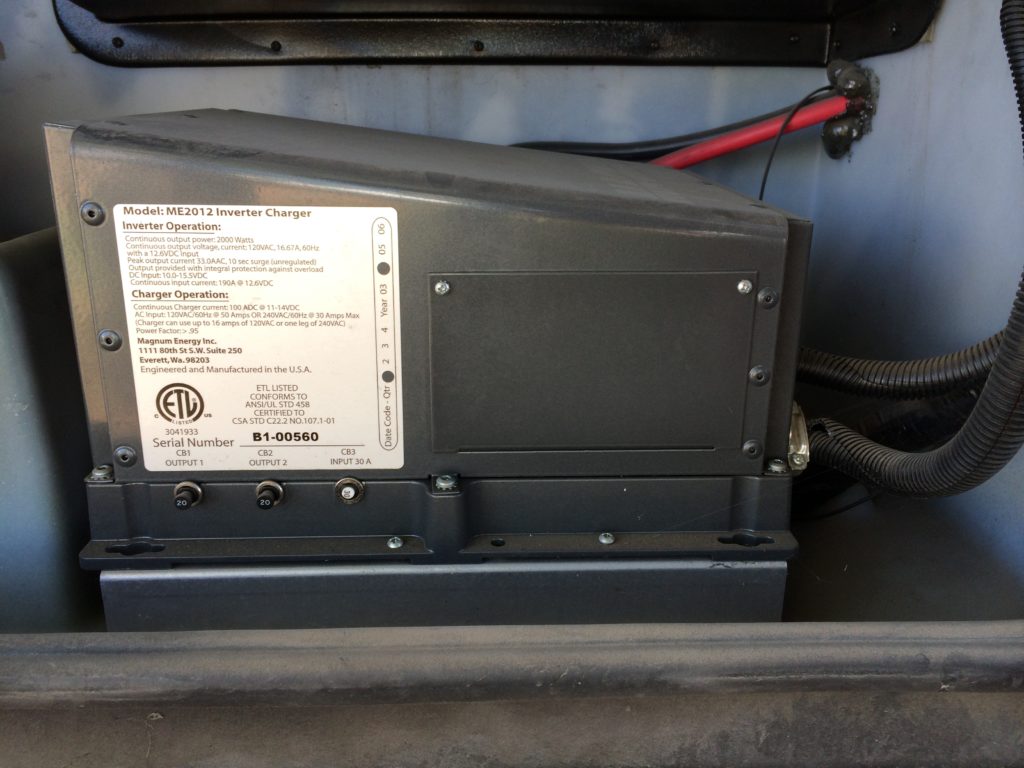

We got two 160 Watt solar panels installed by an RV place in Colorado Springs. We still had our original 2000 Watt ME2012 Modified Sine Inverter.

February 2015

Replaced our 4 batteries that were 7 years old with new Flooded Deka 235 AH, our existing watering system moved right over.

February 2015

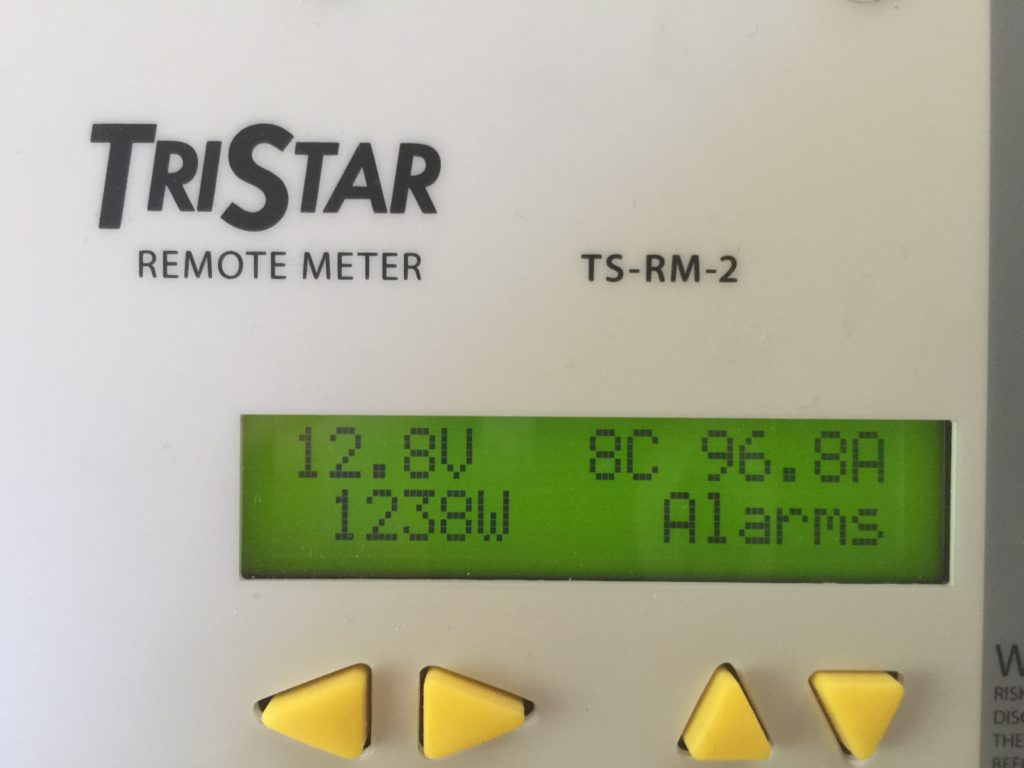

Added 2 more panels for a total of 640 Watt and replaced the controller with a 45 ampere Morningstar Tristar MPPT45.

March 2015

Upgraded inverter to Magnum MS2012 2000 Watt PureSine. Efficiency on running high loads increased over 20% from 200 amperes to 160 amperes when using the Microwave oven.

April 2015

Added 3 Kyocera 260 Watt solar panels on the trailer. The trailer is used to transport our Jeep that does not flat tow since it is being run hard off-road. The power is transferred to the RV with a DC connection with Anderson Plugs to disconnect when driving.

April 2015

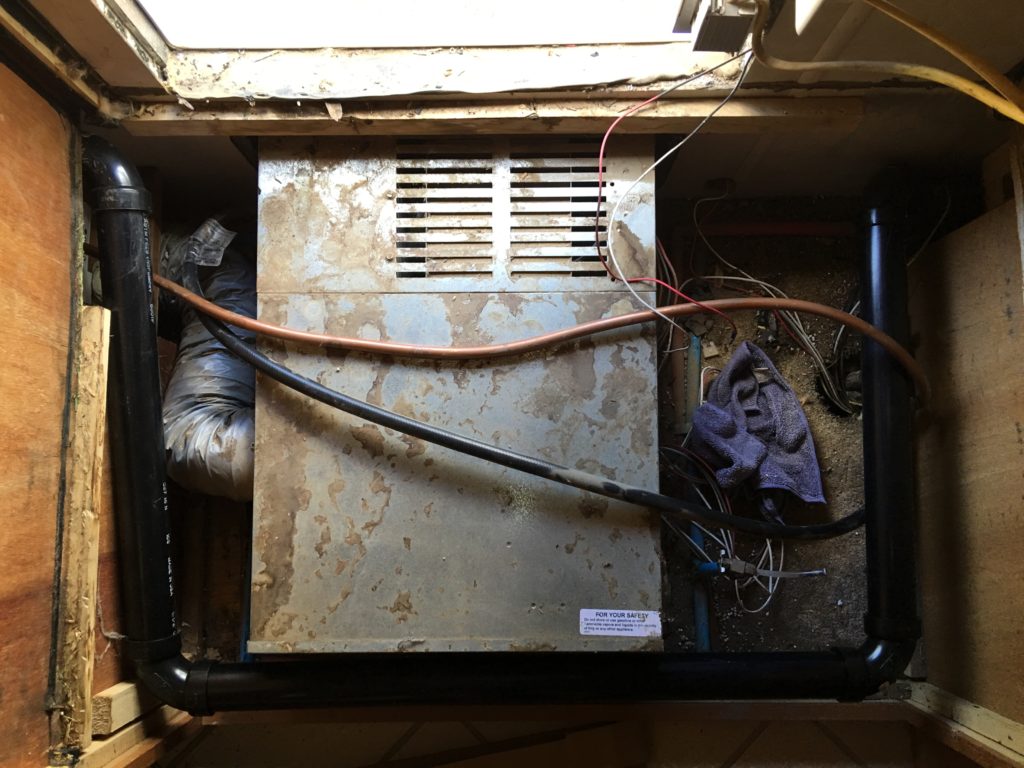

A frame was built to raise the engine batteries to a platform above the house batteries. This allowed for 8 house batteries (8 x Deka 235 AH flooded). All the wiring originally done in the RV for DC was replaced. We did not have a single original wire, less than 3 feet. Now only the needed length of wire is installed, improving losses. When possible was 4/0 wire also used. Below is before and after picture.

April 2015

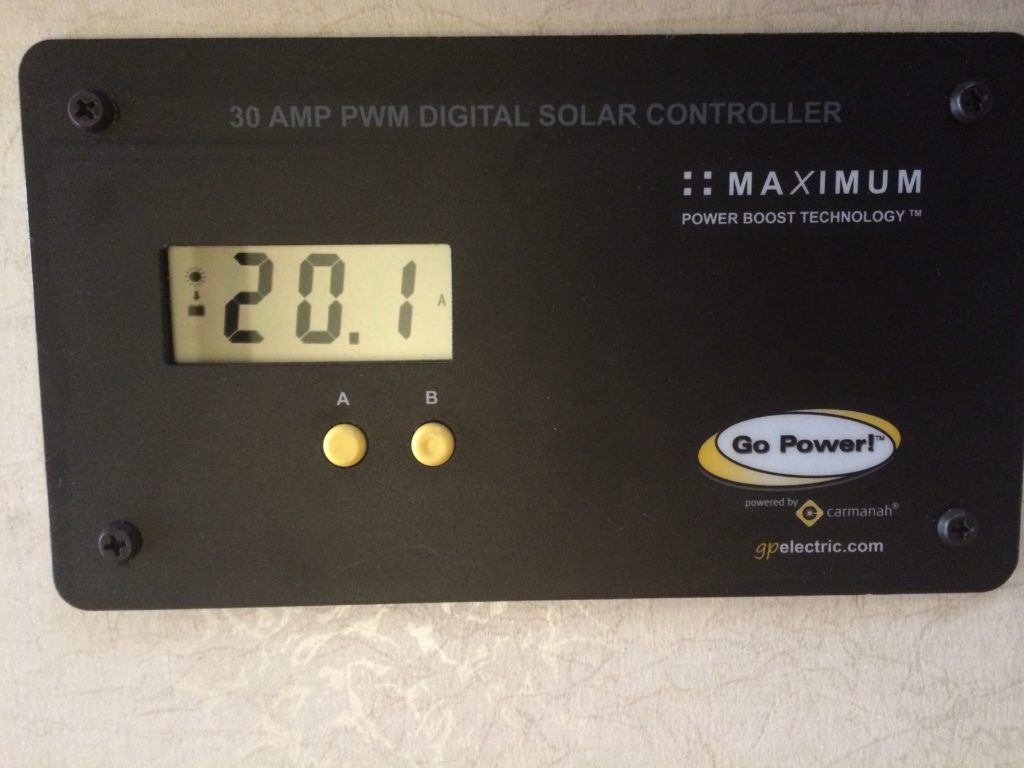

Another panel added to the trailer for a total of 1000 watt. We are now charging more than 60 amperes from the trailer alone.

June 2015

200 Watt of extra 100 Watt panels added to a total of 840 Watt on the roof of the RV. The extra panels ended up not providing any additional power since the poorly matched panels 160 and 100 Watt “12 Volt” panels had a different power curve.

July 2015

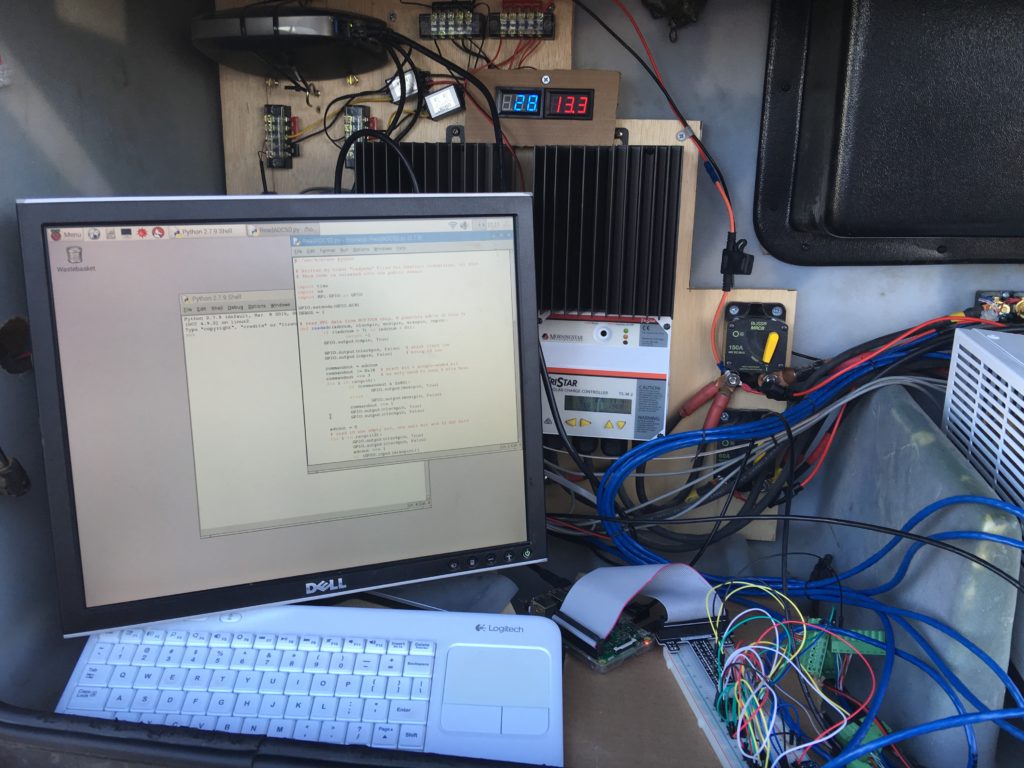

Rebuilt the internal panels to have room for the extra monitoring of the charging from solar.

September 2015

Added a single 12 Volt battery in the trailer to provide light and a small inverter for 120 Volt AC. The controller in the RV was replaced from 45+60 ampere to 2 60 ampere controllers and the 45 went into the trailer. A single 100 AH 12 Volt battery is being charged. Power from the panels can be switched between trailer and RV.

January 2016

Replaced the “12 Volt” panels on the RV with Kyocera 265 Watt residential panels. Also added additionally 2 Kyocera 260 Watt panels on the trailer.

March 2016

The Water tank was insulated and the 120 Volt AC is used with reduced voltage (60 volt AC) to heat the water in 4 hours. With the reduced voltage is the water heater not loading the inverter very high.

April 2016

Working on a complete monitoring system for the battery and charging system. The Raspberry PI is collecting information and provide a website to show the information with graphs.

June 2016

Another 265 Watt Kyocera panel was added to the RV.

June 2016

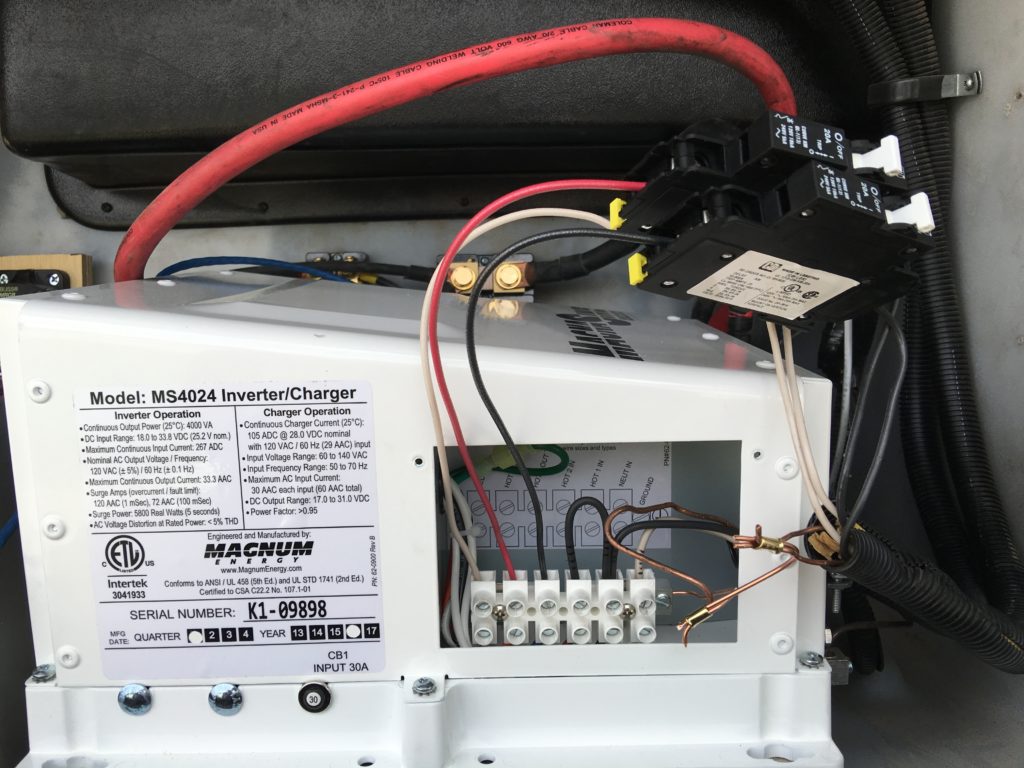

Converted the battery system from 12 Volt to 24 Volt by reconfiguring the wiring, replacing the inverter with a 4000 Watt Magnum MS4024. A small breaker box was mounted because the new inverter did not have built-in 20 Ampere breakers. A Samlex 24 –> 12 Volt DC converter was added to provide power for the light and other 12 Volt loads, the converter provides stable voltage 24/7 and does not go up and down based on loads and charging. Everything for the change was isolated to the battery and inverter section of the RV. A small 50 Watt solar panel is used to maintain the voltage on the engine batteries when parked. Many changes to the DC wiring was done, the Generator is now started from the engine batteries.

June 2016

Did some rewiring of the electrical 120 Volt AC in the RV, we can now run Air Condition and other things directly on the 4000 Watt 24 Volt inverter. The inverter has no problem starting the Air Condition even if we also use the Microwave Oven at the same time. But we have to balance the two phases to not exceed the 20 Ampere breaker. The wire is 12 Gauge stranded wire that can be connected the normal way (connect the plugs) or directly to an outlet from the Inverter.

July 2016

Added a fifth Kyocera 265 Watt panels to the roof of the RV.

July 2016

Replaced the Norcold 1200 firebomb with a Fisher & Paykel residential refrigerator. The best improvement that was done to the inside of the RV, we can now actually fit food a week and the ice cream stays cold. The new refrigerator uses 1-1.4 kWh per day and we can keep our propane for heating. We only need to refill the propane every second month in the winter and can run the whole summer on the tank. The Microwave was upgraded to a stainless-steel version too.

December 2016

The steel trailer that weighed 4500 pounds empty was replaced with an all-aluminum trailer weighing 3050 pounds. The new trailer has the axles placed much better and provide less load on the hitch compared to the old trailer. To maximize the amount of energy captured was long SolarWorld XL 345 Watt panels added, covering 80% or more of the roof.

January 2017

A battery box was added in the floor of the trailer to support 4 190 AH AGM batteries. A complete off-grid setup was added in the trailer with a Magnum MS4024 PAE inverter. This inverter can supply 240 Volt AC and we can run a large welder or even attach the RV directly to the 50 AMP circuit.

March 2017

Bought 6 Battleborn 12 Volt Lithium batteries to replace the 8 Deka flooded batteries. The batteries dropped right in and adjusted charging to AGM and using no temperature adjustment. Going from 5.3 kWh to 7.2 kWh useful storage. The stable voltage from the Lithium also made for a lot of efficiency improvements.

June 2017

Upgraded all the solar panels on the RV to SolarWorld XL 345 Watt panels. The total power is now 2070 watt on the roof of the RV. The panels are mounted on rails 6 inches above the roof to allow vents to open and skylight to still work as normal. Light still come through a solar panel so some light is still coming from the vents, but always like being parked in the shade.

June 2017

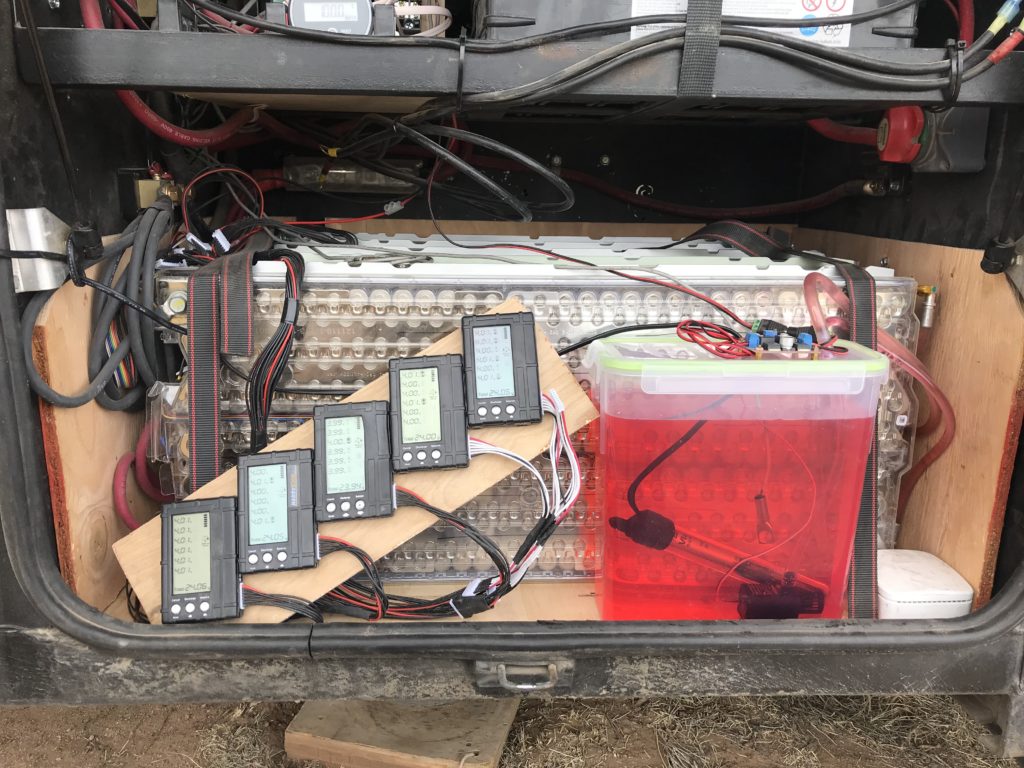

Installed 4 battery modules from a Tesla Model S as our battery pack. Increasing the storage to 16 KWh of useful energy. The energy density is very high for the Tesla Modules. The same space that could have 8 flooded batteries with 5.3 KWh now house the tesla Modules with 16 KWh (20 KWH if we charged them 100%). The Tenergy 5 in 1 device is used to manually trigger a balancing on the cell each month.

June 2017

Replaced a chair with an electric fireplace integrated into a new media center we built. Now running electric heaters in the morning. The Fireplace is wired to a special circuit that only allow draining the battery to 40% with the heater. This circuit reconnects when the charge level gets above 80%.

July 2017

The AGM batteries in the trailer were replaced with 2 of the Battleborn Lithium batteries. When the battery box gets expanded a little more is 4 lithium batteries going to be used in the trailer.

July 2017

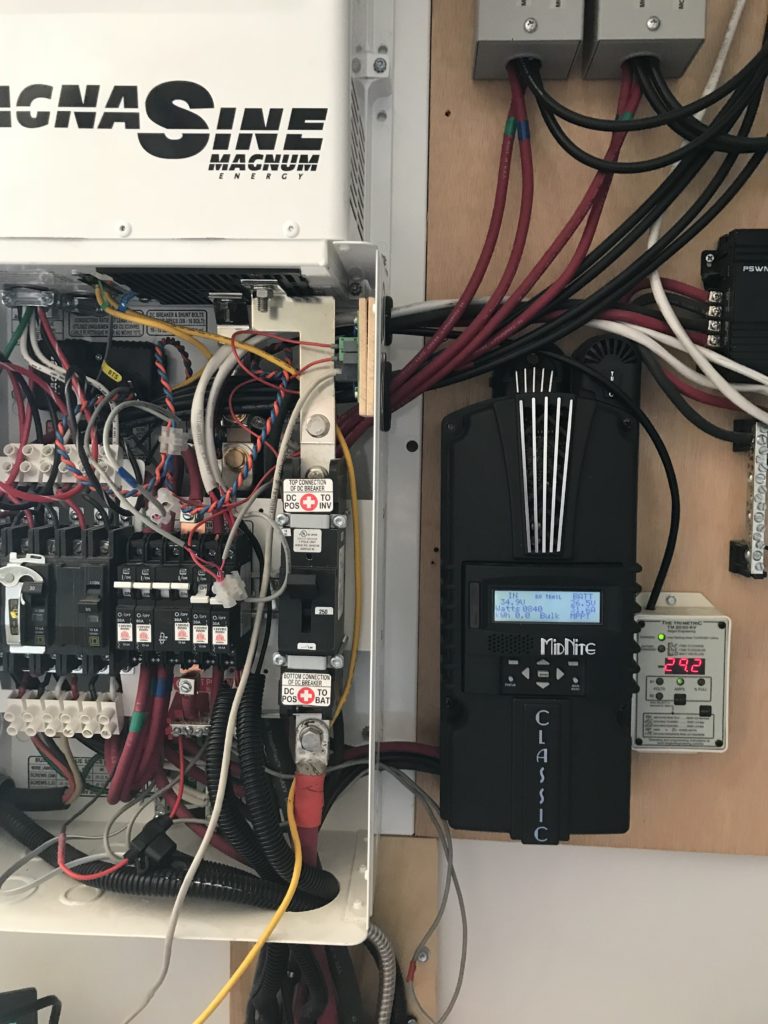

Tested with MidNite Controllers for a short time. The controllers have multiple fans and the electric room is pretty dusty.

January 2018

The batteries in the trailer were sold and new Battleborn CG6 sized was added, the capacity is now double.

February 2018

The MorningStar controller had a hardware issue and only allowed 20 amperes charging. One of the spare MidNite controllers was used to replace. The trailer environment is much cleaner and less dusty.

May 2018

An extra Tesla Module that had been used for testing was added to the battery bank for a total of 26.5 kWh or around 20 kWh of useful storage. The battery box is now lined with ¼ inch plywood to limit the chance of shorting a battery during mounting and insulation for lower temperatures.

The balancing was upgraded from the balancers that manually required starting a balance. The Battery Medics are now balancing the batteries when the voltage is above 24 Volt. This is at full charge so the loss of energy is only when charging.

The fluid container is also updated and now allow more than doubles the capacity.

July 2018

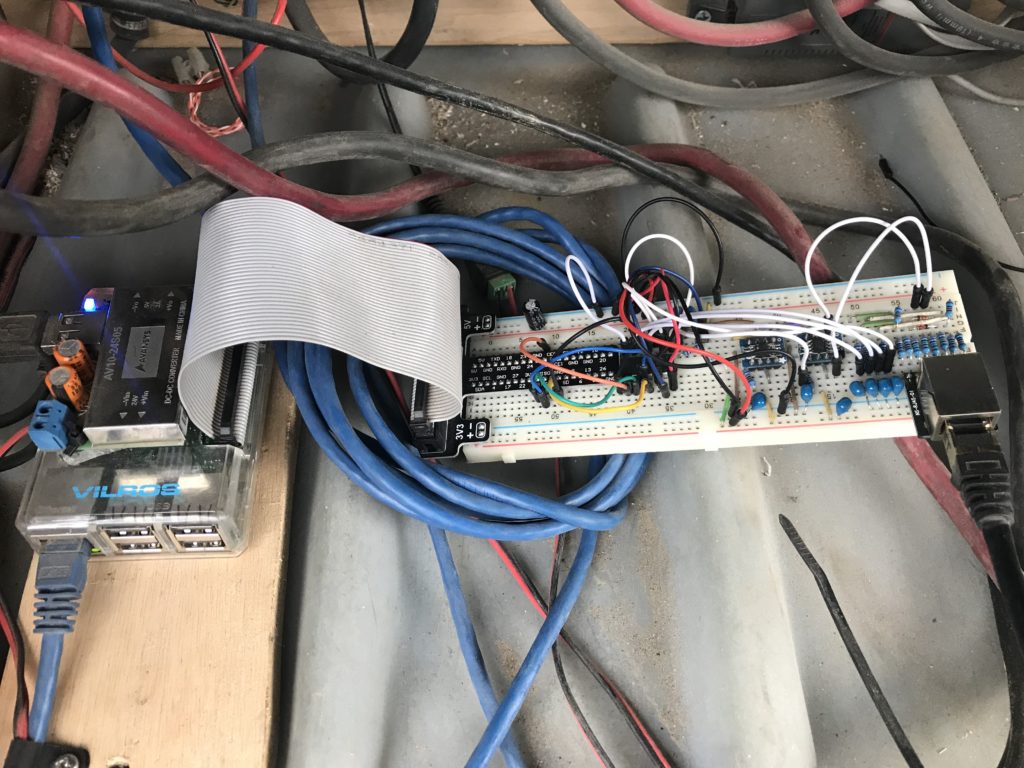

The Raspberry Pi that use to only talk with the Solar Controllers now also tracks the Battery State of Charge using a custom board.

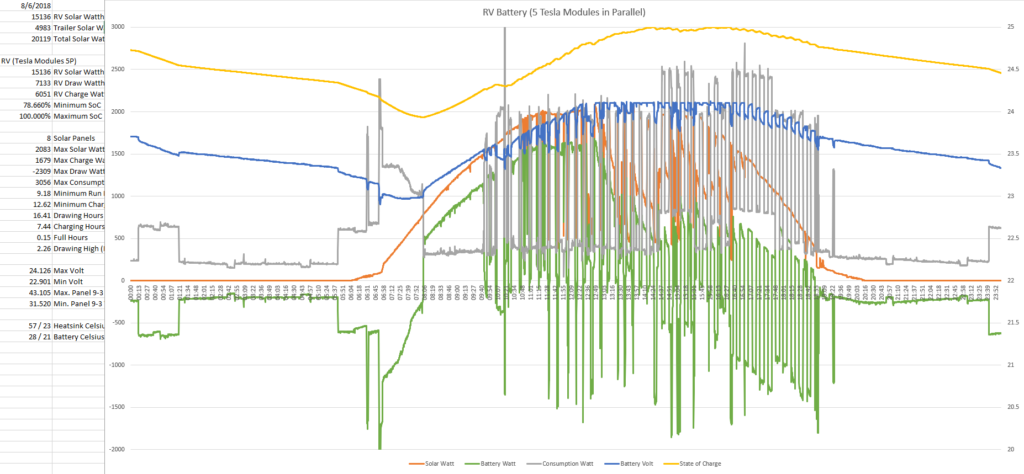

The data now allow the Excel spreadsheet to track the state of charge and the actual drain from the battery.

October 2018

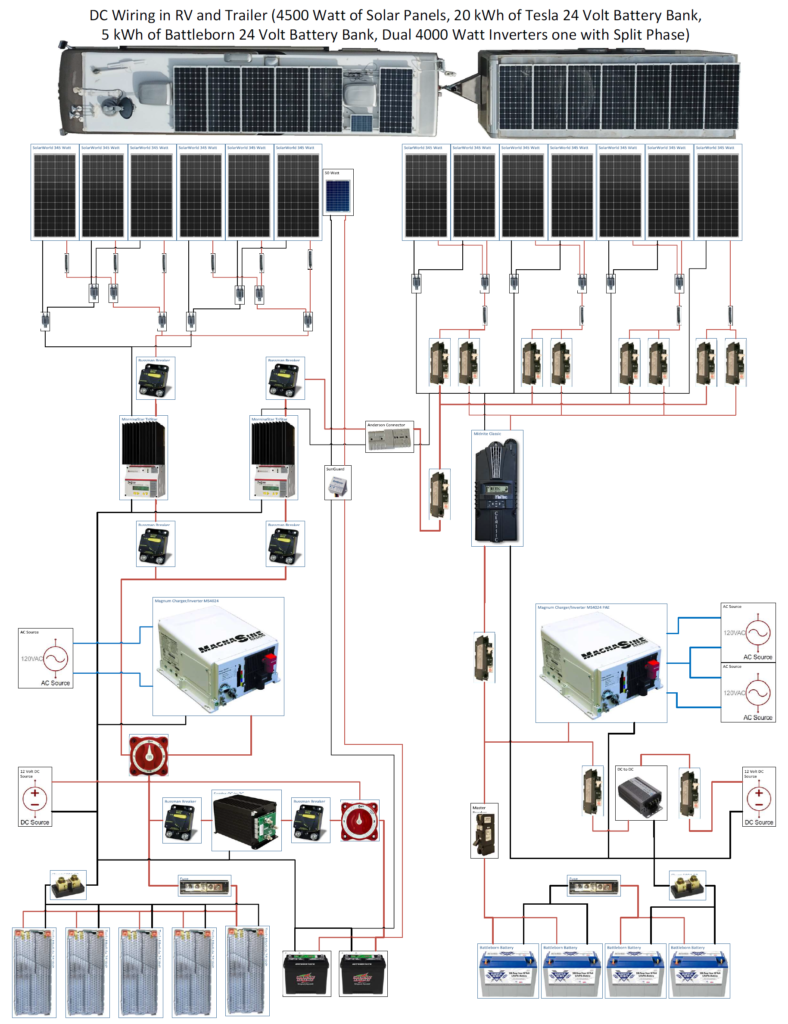

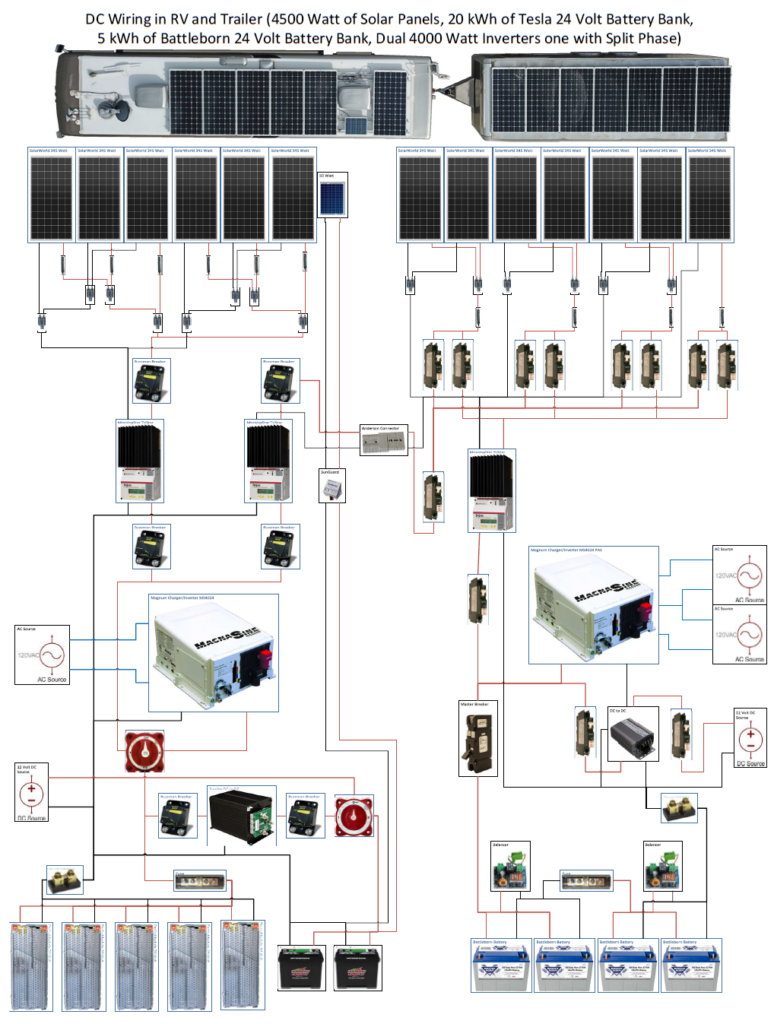

Got around to create a wiring diagram with Visio. Download the detailed PDF Wiring Diagram RV and Trailer.

November 2019

We have had issues with the control board for the Waterheater since the spring of 2019. Control is now implemented for the 120 Volt Heating Element based on a simple sensor and relay bought from Amazon. An added benefit is we can now reduce the temperature and daily power required to heat the 10 gallons of water. This Water Heater from Solar blog has more details about the energy savings.

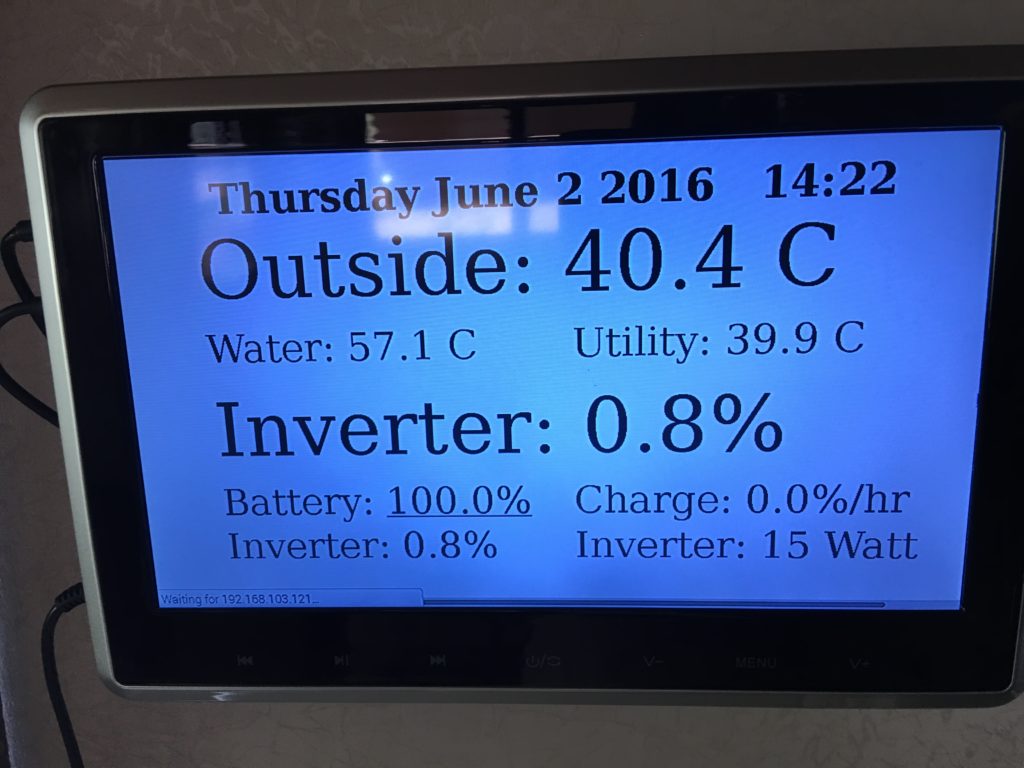

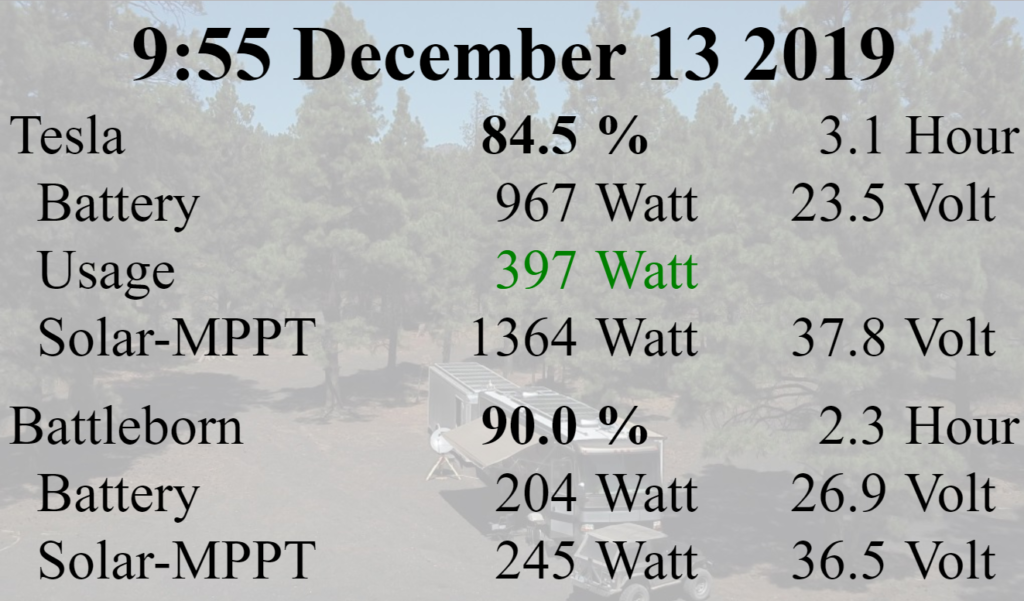

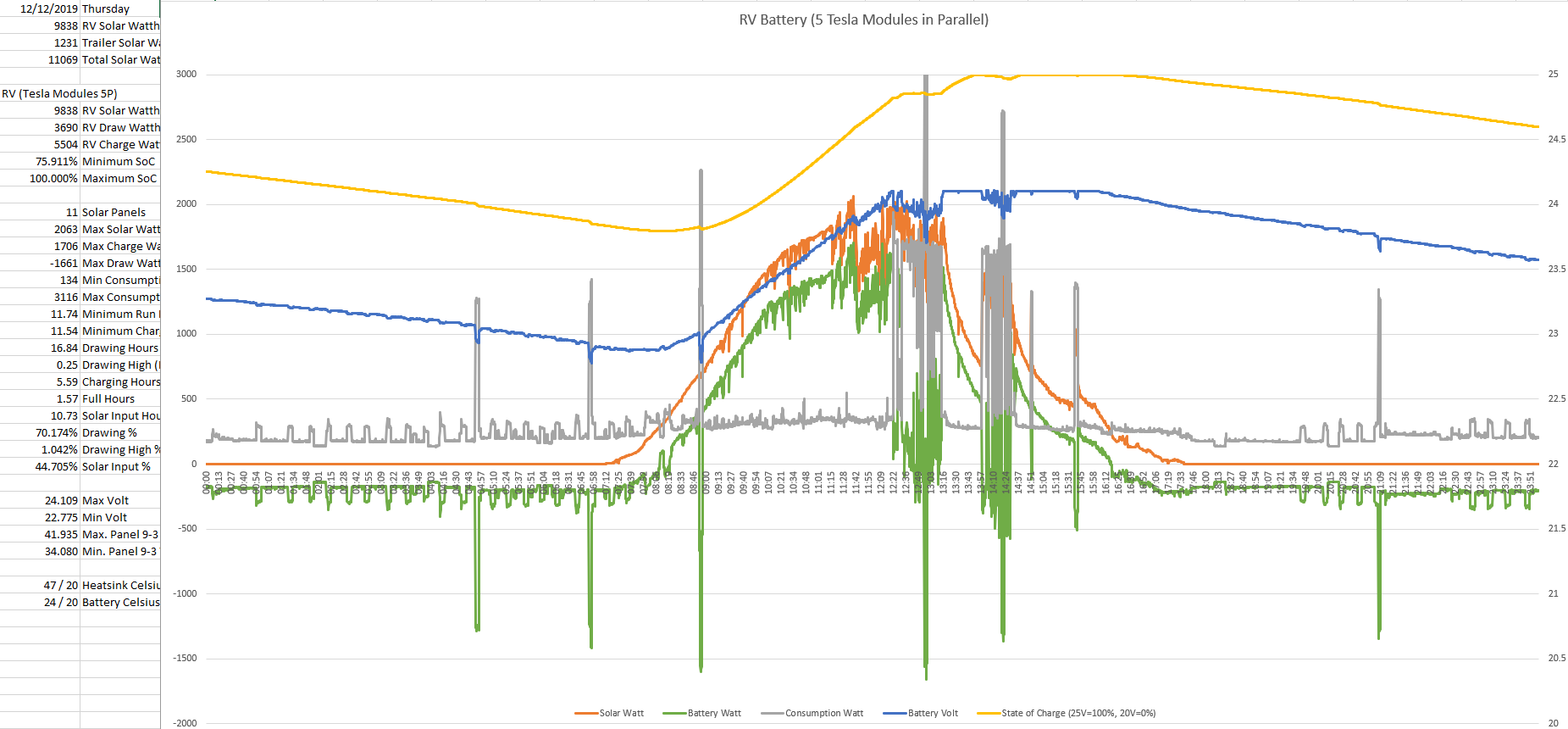

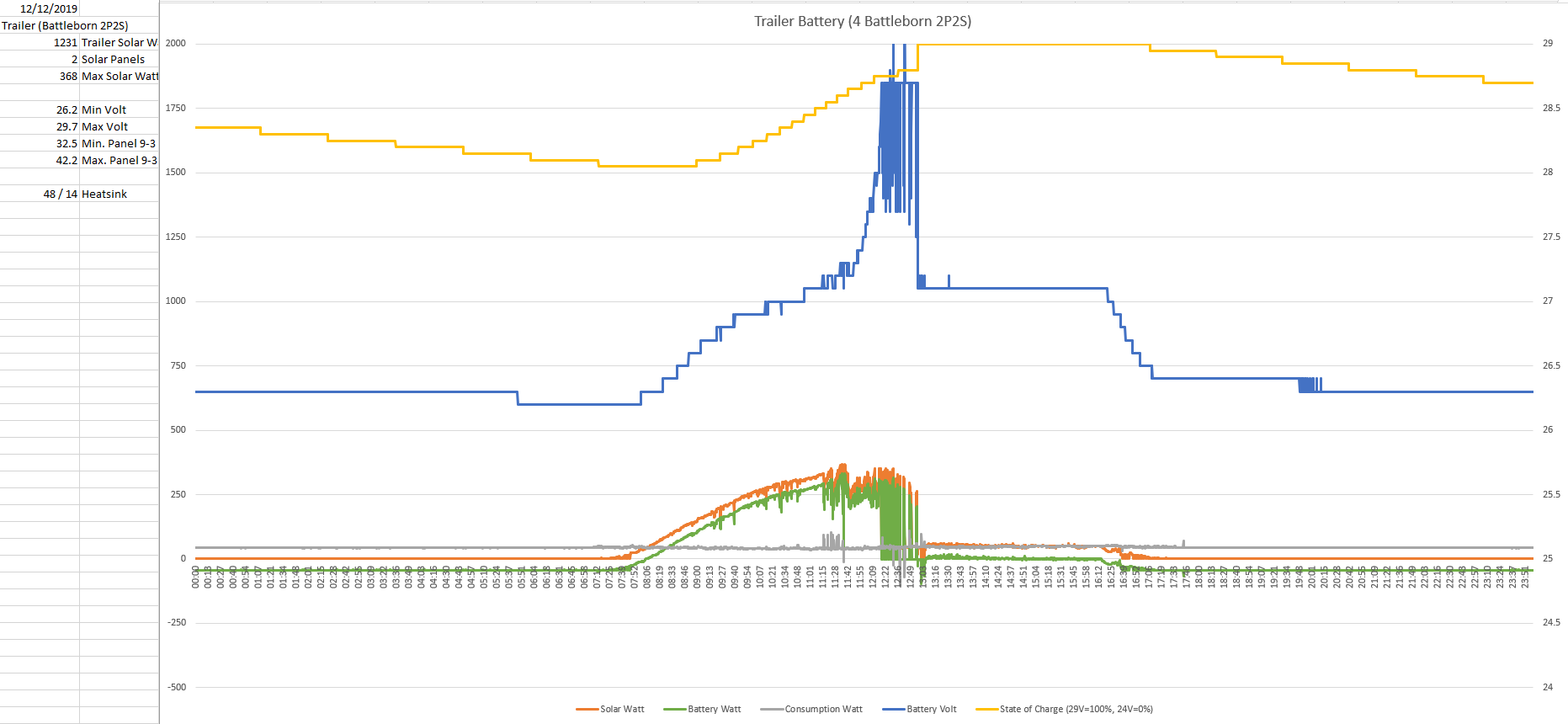

December 2019

The software for the Raspberry PI system has been updated with small features constantly. After adding a MidNite WhizBang Jr. in the trailer can the screen also display the battery status in the trailer.

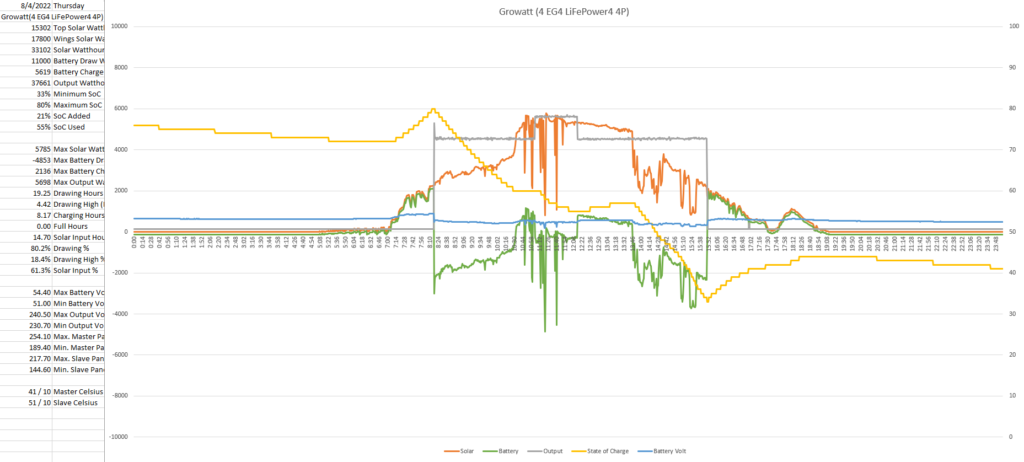

The data is captured every 15 seconds from the solar controllers and the shunt by the Raspberry Pi withExcel can a lot of useful graphs give an overview.

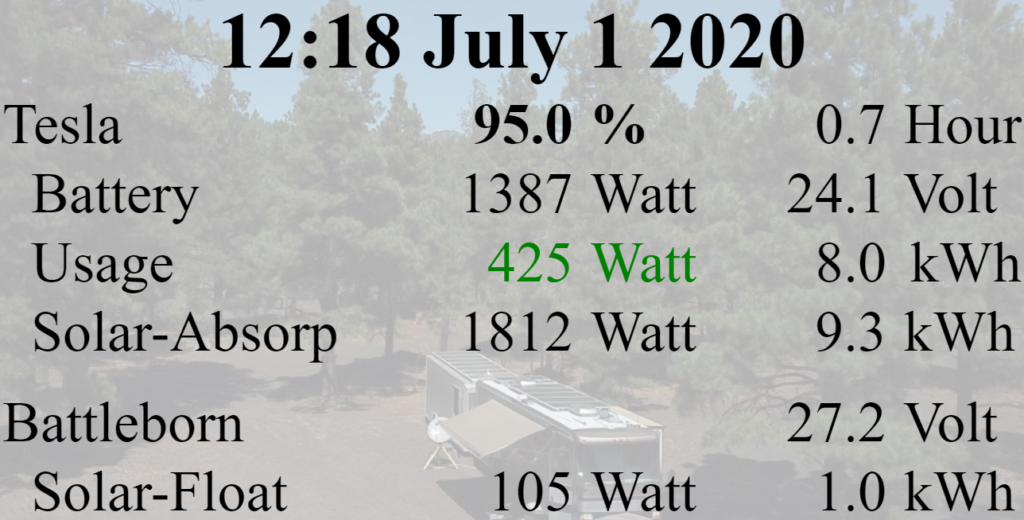

Daily RV Status

Daily Trailer Status

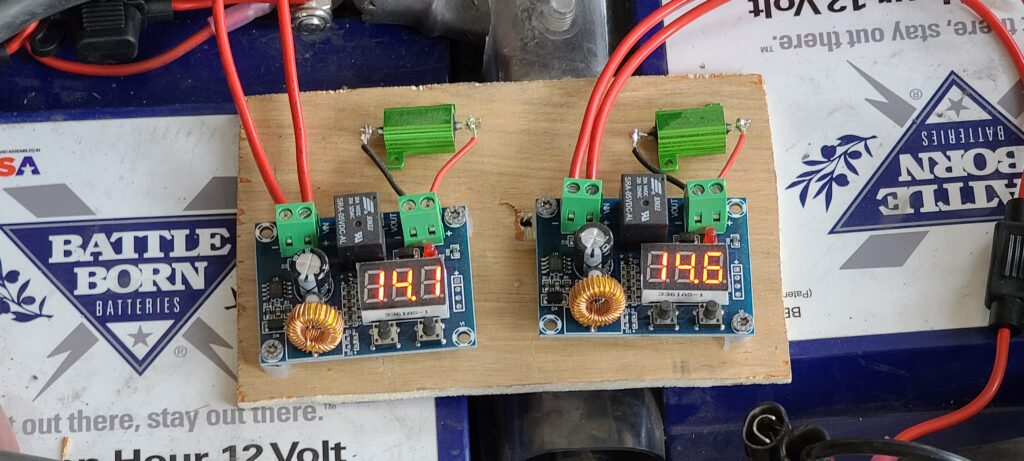

June 2020

The 4 Battleborn Batteries had over time been more and more out of balance ending with one 12 Volt part being in battery disconnect when the other was not fully charged. A solution with a Voltage dependent switch and a resistor brought it back in balance.

The cover was also cut and a piece of plexiglass added to monitor from outside.

The MidNite Solar Controller was not performing very well when running in float under high loads. The battery was drained during the day when another RV was hooked to the trailers inverter. The MidNite Controller was also noisy under load with multiple fans. A 60 Ampere MorningStar Solar Controller with no fans was installed instead. 4 Additional outlets were also installed in the empty space of the breaker box with the 30/50 Amp outlets.

4 Additional outlets were also installed in the empty space of the breaker box with the 30/50 Amp outlets.

The internal display was showing the instant generation and consumption data. The information is now updated to also include the summarized information for daily kWh.

Wiring Diagram updated Wiring Diagram RV and Trailer

July 2020

The original Sub=panel with two 20 Ampere breakers was causing problems when running high loads like the Air Condition together with other loads. When the breaker popped was other things disconnected like networking and refrigerator. The Magnum MS4024 is capable of 4000 Watt sustained loads and 5000 Watt for 5 minutes so disconnects based on only 20 Ampere (2400 Watt) watt, not a good solution. A new breaker panel with six 20 Ampere breakers with dedicated circuits for networking and base loads.

The box also allowed mounting additional outlets in the top so the Battery Heating is now connecting directly to the breaker box too.

December 2020

The diesel generator is now replaced with a 70 gallon water tank. This is a lot more useful option since we never needed the generator with our solar setup.

The water tank now take most of the space. It is filled manually from a hose and pumped into the regular 100 gallon water tank to be used.

Even we never needed the generator is it always nice to have a backup so a small Honda generator is now carried in the trailer. This has been used by other people when boon docking, but not needed for our own power.

May 2022

We have been using the Tesla Modules for our storage for almost 5 years. The solution provided a lot of storage in a small weight and volume. But it came with a need to watch the balancing and heating to ensure a secure system. With our new Tesla that we have taken for long road trips and stored the motorhome was the systems securing the battery bank causing worries. Another issue was that one battery module had went so far of balancing that the small balancers could not keep it balanced. With those issues was a more hands-off solution needed. So the space allowed for 8 Battleborn batteries with 10 kWh of useful storage.

The reduction from 20 kWh of storage with the Tesla Modules to the 10 kWh make it from 3 days to 1 day and 2 nights of useful storage. This has reduced our ability to handle bad weather without reduction in consumption, but we are adding a lot more storage in the trailer with an upgrade to charge the Tesla, this can also be used to charge the RV battery bank if needed.

May 2022

The solar setup was using older solar panels with less efficient 345 Watt solar panels. We also only had 6 solar panels, but the roof on the RV has room for more solar panels if they was raised above the air conditioners. The panels and rack was upgraded to eight 445 Watt solar panels.

To clear the air condition unit was the rails we already used raised. With some cross braces is the rack really solid with minimal weight added compared to the previous install. The raised panels also allowed the vents to open a lot more for better airflow.

August 2022

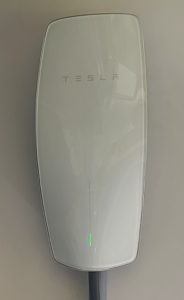

With the electric Tesla is it possible to generate a lot of power from solar and convert it to driving miles. We used the inverter in the RV, it worked but made the system being quite loaded and operate very hot. The storage in the trailer was too small to run any time of charging without draining the batteries on a cloudy day and the inverter was limited to 4 kW of charging. So a rethinking was needed if doing some meaningful charging.

The solar panels are now stored on the roof of the trailer in 3 layers when driving. After arriving at the campsite is the “wings” manually pulled out and provide a lot more power. Twelve of the existing 345 Watt solar panels from the RV and trailer is used on the wings and the top has six new 445 watt solar panels. This gives a total of 6.8 kW of Solar Panels for charging. The last 345 watt solar panel is charging a single Battleborn battery that supply 12 Volt for lights, jack and brakes in the trailer. The primary large system is shut down when driving.

The StarLink dish also got a new home mounted on the front of the trailer. This cause some shading on the front soar panels that is used for 12 Volt charging. but this is so overpowered already.

Internal in the trailer has everything been replaced. Dual Growatt inverters working in parallel are now capable of providing 10 kW at 240 Volt at 60 Hertz. The combination of Solar Charge Controller and Inverter is making a 95% efficient conversion from solar power to the 240 Volt needed for the Tesla Wall Charger. Most of US equipment is using 120 Volt 60 Hertz and the Split Phase Transformer create a neutral between the 240 Volt for 2 phases at 120 Volt. This solution is limited to 5 kW maximum, but more than enough for the equipment we need. This is also used for potentially charging the RV with a limited 10 kWh battery bank.

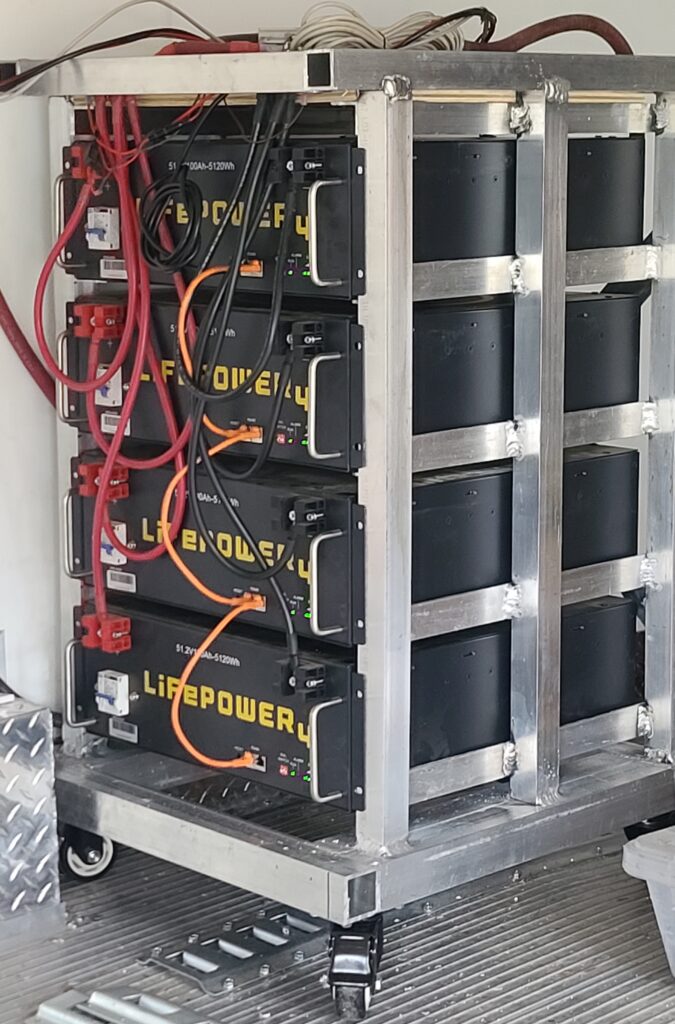

Energy is stored in a 20 kWh battery bank based on 4 Rackmount 48 Volt modules. This solution is now so competitive priced that even building a battery bank from Tesla Modules is more expensive. The batteries are also Lithium Iron Phosphate that is a much higher cycles and secure. The rack mount modules contain BMS and many other features that ensure proper charging and discharging.

Energy is stored in a 20 kWh battery bank based on 4 Rackmount 48 Volt modules. This solution is now so competitive priced that even building a battery bank from Tesla Modules is more expensive. The batteries are also Lithium Iron Phosphate that is a much higher cycles and secure. The rack mount modules contain BMS and many other features that ensure proper charging and discharging.

The Growatt inverters are also communication with the batteries to control the charging based on State of Charge. Currently is the batteries mounted in a rack that can roll around but they are going to be permanently mounted on the floor of the trailer in a future update.

The system if rarely being used to the full potential since we do not drive enough in the Tesla, we need to driver 100 miles at least each day to keep the car at low enough state of charge. Above is the data from a day when the car was charged for 7.5 hour with 20 Ampere @ 240 Volt or 5 kW. We did not end the day with the same state of charge in the battery bank as we started, but the stored energy in the trailer can charge the Tesla 20% even with no solar input at night. The system can support 40 Ampere charging for hours, but this typically drain our batteries a lot, but if needed can we add 9 kW or 10% State of Charge per hour if needed for a quick charge.

The Tesla Wall Charger is not able to be controlled with a simple signal and the Tesla can minimum be set for a 50% charge Limit. So a system that cut power to the charger is going to be implemented in the future.

November 2022

To charge the Tesla in the winter was the current 10700 on the roof not really sufficient. To solve this was a large ground deploy array added to the trailer Growatt inverters. The total Solar array is 19100 Watt.

By matching the voltage from the solar panels on the roof of the trailer can these used 280 Watt panels be used with the existing controllers. A Diode was also added on all positive lines to prevent backflow of current if voltage turns out to be slightly off during float. The 30 Panels added was 8400 Watt. Some of the panels are sitting at 45 degree angle optimal for winter in the Phoenix area.

After a mistake with flipping breakers in the wrong order was the Growatt solar controllers/inverters fried. It turned out the warranty did cover and new Inverters was shipped from Signature Solar. A spare unit is now on the wall for the future.

August 2023

We have been using a 2 burner electric cooking plate for a long time instead of the gas. the plate was mounted on top of the gas if we needed to revert back to gas. The reverting to gas was never necessary and we have now installed a 2 burner induction cook top with a maximum draw of 1800 watt. A dedicated circuit from the breaker panel now supply this.

When we removed the gas burner stow was it also possible to make a drawer for the knives and other utensils.

February 2024

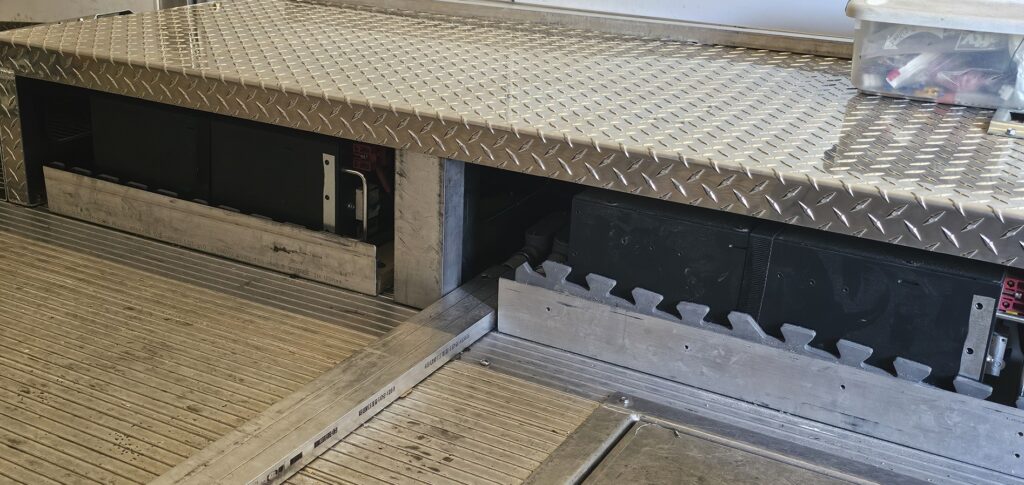

The batteries in the trailer was placed on a mobile rack weighing ~500 pounds. Every time we travelled was the batteries disconnected and moved to the front of the trailer causing a lot of extra weight on the hitch. It was also necessary to disconnect all the power. A set of ramps has been added to the trailer with space for the batteries below and additional storage. Putting the batteries behind the axle of the trailer has improved the balance and hitch weight. When driving the Tesla into the trailer can the driver fender well also stay attached and a lot more clearance on the side of the car.

The wiring from left to right side run in 1×1 inch aluminum tubing.

April 2024

A spare inverter has been hanging on the wall of the trailer. It has now been wired to handle additional ground deployed solar panels and a 22 Ampere inverter for charging a second electric car using the mobile charger and a NEMA 6-50 outlet.

With the extra charge controller can more solar panels be deployed on the ground temporary. There is more than 23000 Watt of solar panels deployed in the picture below.

The trailer wall of electronics is now close to full.

May 2024

The latest wiring diagram is now available. It can also be found in a PDF Wiring Diagram RV and Trailer with all the details.